LINCOLNSHIRE, Ill., Nov 6, 2025 – Advanced driver assistance systems (ADAS) are now standard across modern vehicles, delivering critical safety features such as adaptive cruise control, lane departure warning and automatic emergency braking. For independent shops, this rapid growth presents both opportunity and challenge. Every component replacement, alignment or windshield repair has the potential to affect a vehicle’s ADAS performance, making recalibration an essential part of today’s service and repair process.

This article explores why ADAS recalibration matters, the different types of calibration required and how Snap-on® diagnostic platforms equip technicians with the service information, guided workflows and exclusive features to complete these complex jobs with accuracy and confidence.

Why ADAS Recalibration Matters

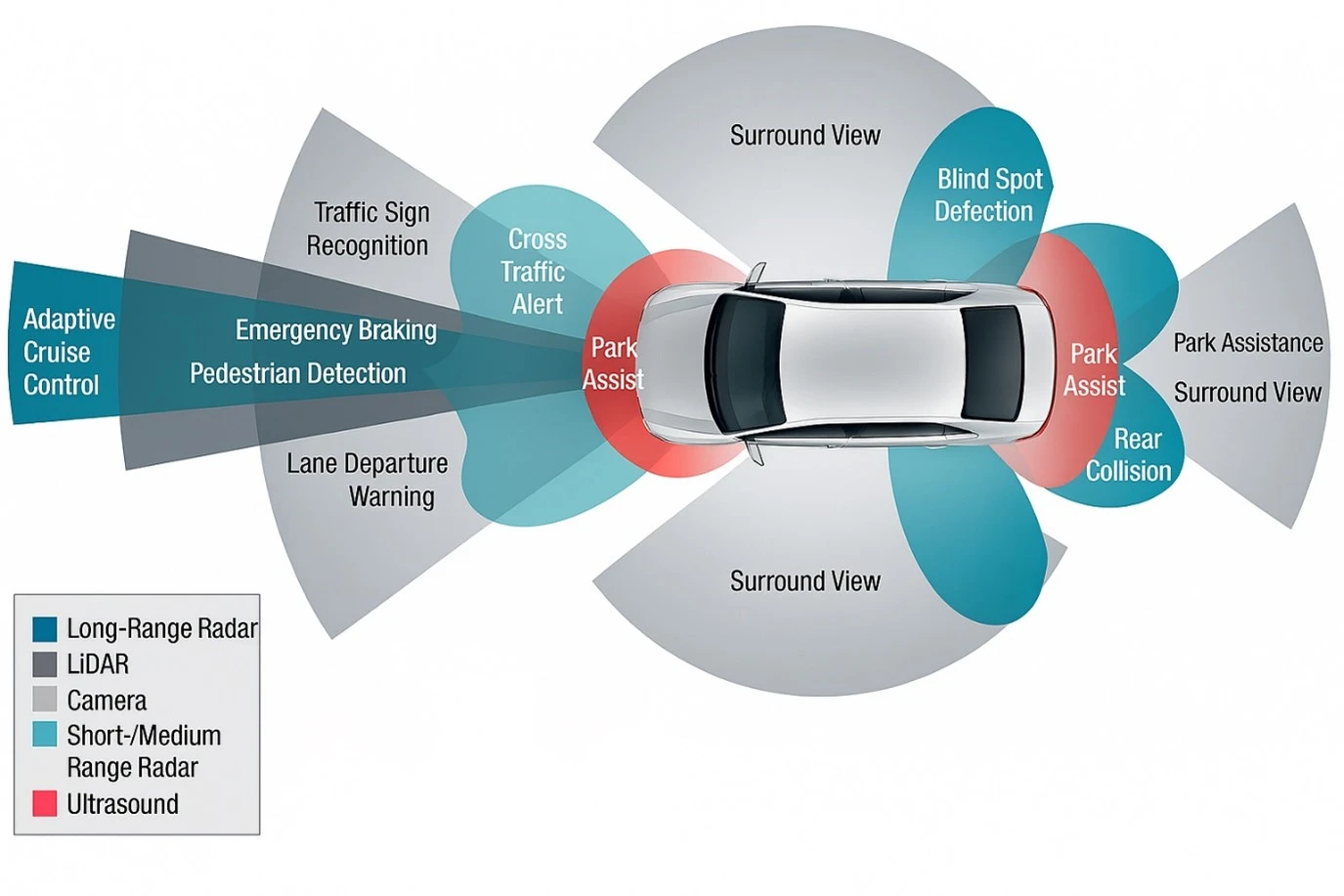

ADAS technologies depend on a precise network of cameras, radar, lidar and ultrasonic sensors. Even a millimeter of misalignment can compromise performance. For example, a forward-facing radar mounted slightly off-center may cause adaptive cruise control to brake late or fail to detect obstacles accurately. Similarly, misaligned cameras can disrupt lane-keeping systems or blind spot monitoring.

Recalibration restores the system to manufacturer specifications, ensuring safety features operate as intended. It also provides shops with a vital revenue opportunity. With ADAS present in most vehicles built since 2016, demand for recalibration services will only increase. Customers expect not just a repair, but the reassurance that their vehicle’s safety systems are fully functional after work is completed.

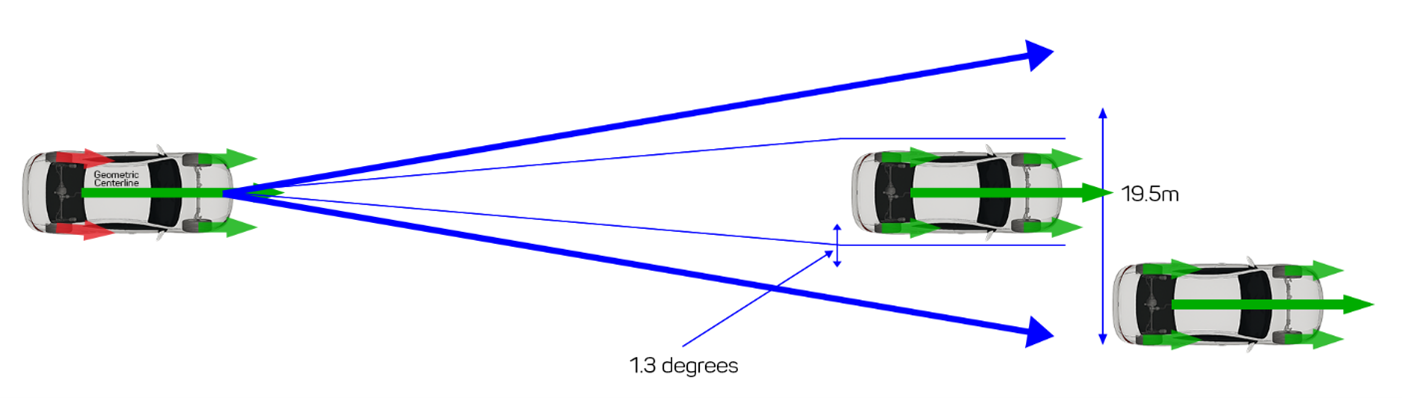

Consider a front-facing camera with a 7-degree field of view, covering about 60 feet at a 500-foot distance. A road lane is around 12 feet wide; a small misalignment of ½ an inch can significantly affect the camera’s ability to correctly interpret lane markings or obstacles.

Even minor misalignments can cause hazards. Recalibration ensures systems function correctly. Each manufacturer has unique recalibration steps. Snap-on tools simplify this by delivering OEM-specific guidance tailored to the vehicle systems, reducing errors and saving time.

Types of ADAS Recalibration

Snap-on diagnostic tools support the full range of manufacturer-specified recalibration methods, with built-in step-by-step workflows:

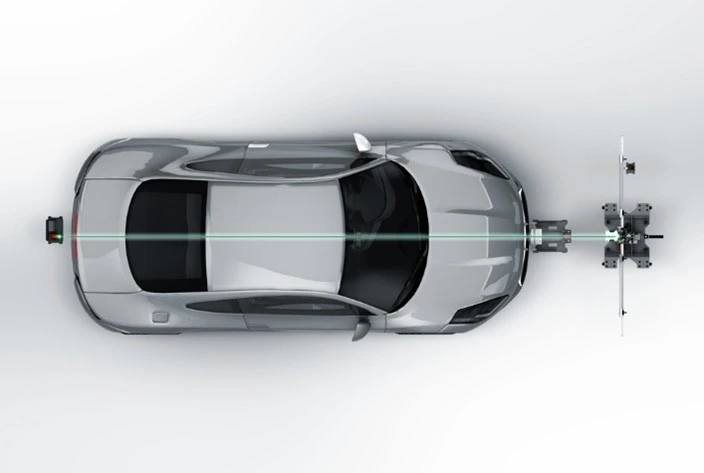

• Static recalibration – uses physical targets or patterns in a controlled workshop environment. The tool communicates with the vehicle to verify sensor accuracy.

• Dynamic recalibration – performed on the road under specific speed, distance and traffic conditions. The tool provides live prompts and confirmation.

• Initialization – required after new component installation, setting baseline system parameters to restore function.

Building a Consistent Diagnostic Workflow

The recalibration process fits into a broader workflow:

1. Pre-scan: identify fitted systems and fault codes

2. Repair: replace or adjust components

3. Recalibrate: perform required procedures with the Snap-on platform and ADAS recalibration equipment

4. Post-scan: after completing the repair, perform a post-scan to confirm it was fixed properly

This process applies whether addressing a single ADAS fault or a multi-system repair after a collision.

Accurate recalibration requires the right workshop setup:

• Space: clear area for targets and access

• Lighting: consistent for sensor recognition

• Level floor: to ensure accurate vehicle and target alignment

• Clear line of sight: no obstructions between sensors and targets

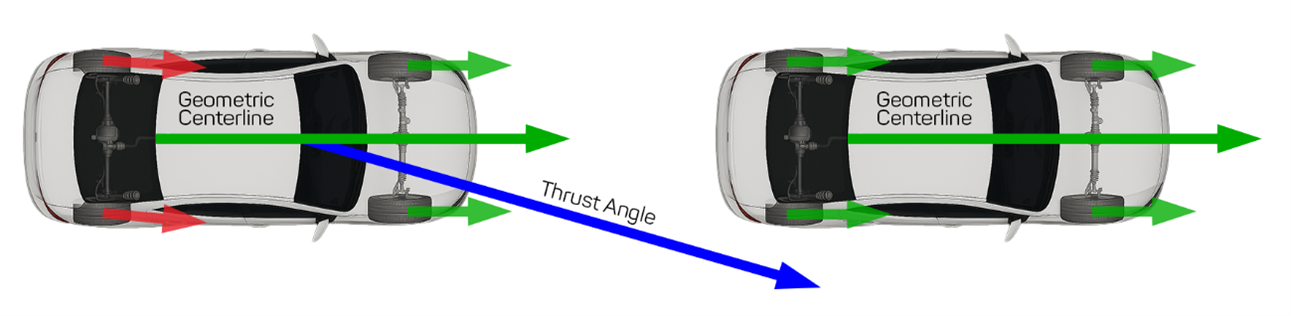

Wheel Alignment Accuracy Matters

Many OEMs require wheel alignment checks before calibration can begin. A thrust angle error, incorrect ride height or faulty steering angle sensor will all distort ADAS performance. That’s why Snap-on software often includes steering angle resets within recalibration workflows, ensuring accuracy at every step. For physical target placement, equipment such as the John Bean® Tru-Point™ or EZ-ADAS™ supports OEM-compliant procedures with laser and camera precision.

The Importance of Service and Repair Information for ADAS

Successful ADAS recalibration goes beyond simply connecting a diagnostic tool. Technicians need up-to-date, vehicle-specific service and repair information to guide every step of the process. This includes:

• OEM calibration procedures for each ADAS feature

• Precise target placement measurements and environmental requirements

• Torque settings, wiring diagrams and component locations

• Pre- and post-scan functions quickly identify all codes for every system. Reports are automatically

saved to the Snap-on Cloud and can be easily shared with customers or insurance companies.

Without this information, the risk of incomplete or inaccurate calibration increases — potentially leaving safety-critical systems unreliable.

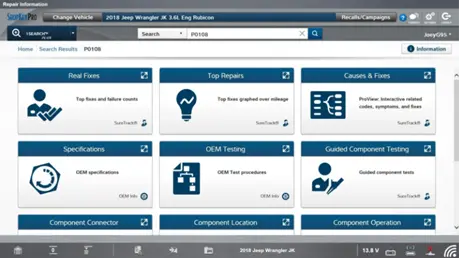

Snap-on diagnostic platforms integrate this essential knowledge directly into the workflow. With ShopKey® Pro and exclusive SureTrack® Real Fixes, technicians gain access to repair information, verified solutions and community-driven insights alongside live diagnostics. This integration ensures recalibration is not just possible, but consistently accurate, efficient and profitable for independent shops.

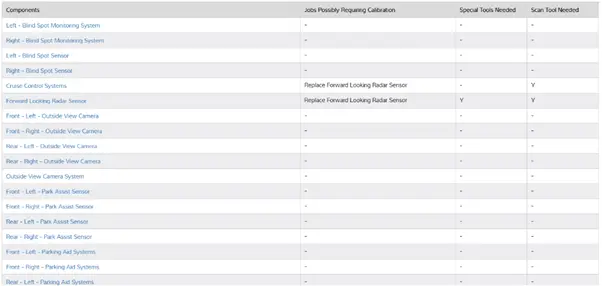

Featuring a VIN-specific ADAS section, ShopKey Pro shows which systems are present, if targets are needed, and which components are involved.

Clicking on a component provides valuable supporting information, including its function, location, and related procedures—enabling more accurate diagnostics and confident repairs.

Conclusion

ADAS recalibration is no longer a specialist job — it’s an everyday requirement for modern vehicles. With Snap-on diagnostic software, technicians have everything they need in one platform: OEM-specific guidance, recalibration workflows, functional tests and integrated reporting.

Speak with a Snap-on Franchisee to learn more about the latest ADAS software coverage and see how it can transform the workshop’s efficiency.

Click here for more on this topic, and for so much more, visit Snap-on’s technical article pages.