Throughout the history of automotive repair, there have been many changes and upgrades to how a reset is done. For example, in the beginning the trip odometer was used to track oil change intervals. An oil change reset back then was resetting the odometer after finishing the job. The beauty was in its simplicity. To reset it, just press, or turn the knob until everything turns back to zeros. Oh, and it was accurate up to a tenth of a mile.

Oil Change Light (left) vs Oil Pressure Warning Light (Right)

Later the odometer was followed by a mileage/date sticker reminder. With the evolution of systems, came the oil change reminder light or message. It is a wonderful notification to remind us to take good care of our vehicle. This is a good example of where a reset comes into play.

Before I go any further with resetting the oil change light, I would be remiss if I did not mention the BIG difference between this indicator light and an oil change warning light or oil change pressure light. For those that don’t know, an oil change light is an oil change reminder, while the oil change warning light is specific to low oil pressure which can lead to serious problems.

In the early 80’s I was the manager of a repair shop that did a lot of oil changes. The shop had a two-car length pit that made for a quick job; therefore, a profitable one.

One afternoon I heard a car pull in that was knocking like crazy. I am talking about that unmistakable bottom end, crankshaft and rod knock. I half way expected a chunk of hot metal to shoot through the oil pan at any moment. One of my team guided the young man driving to pull his car over the pit. As he got out of the car, I stepped over to inquire what he needed, like I didn’t already have a pretty good clue. He said his oil light was on so he needed an oil change.

Remember, oil warning lights came along in the 1950’s to indicate low oil pressure. In 1988, GM™ came out with the first oil change reminder light based strictly on the odometer. From then on, many vehicles had both a warning light and the oil change reminder, providing two different yet very important functions.

This young car owner was highly confused and uninformed. I checked the dip stick and it was bone dry. The vehicle was only a year old with 28,000 miles. He had never changed the oil, or even checked the dipstick before. I don’t believe he knew how until just now. He thought the oil light meant to get it changed. It was way too late now. I wasn’t about to touch this car. I visualized the oil pan filled with ten pounds of dry metal shavings as the engine was obviously shot. I gently told the young man that I believed he needed to take it to the dealership where he had purchased it. There, they could advise him what to do. I suggested that he have it towed, but he was upset and jumped in and rattled away. I do not know how that turned out, I can only guess.

So back, to oil change reminder resets. Before 1988, we would just change the oil then reset the trip odometer, write the date and mileage in a spiral bound maintenance log in the glove box, or have a sticker inside the windshield.

In today’s world, a reset is required to put the reminder back to zero – fresh oil change. How? That depends entirely on the OEM (Original Equipment Manufacturers). Some have a manual reset procedure as seen below from a Snap-on® scan tool’s Oil Specs and Resets:

2016 Toyota® Camry® manual procedures.

Many OEMs require a scan tool to reset the reminder. Such as the 2013 E series BMW®, seen below. In fact, there are resets required for several regular maintenance items. How important are resets/relearns really? Well, if any of these maintenance reminders below are not reset, those systems may not receive service when needed. That could result in expensive damage to the vehicle.

Modern day vehicles have a wide range of required resets. Not performing these resets could result in a comeback, damaged components, or even an unsafe condition.

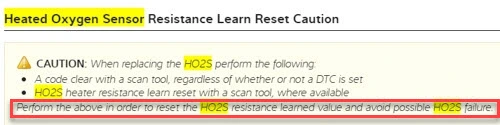

A perfect example is the now infamous, misunderstood issue on GM®. What happens when an oxygen sensor is replaced, but a relearn to reset the heater resistance value, is not performed as cautioned below? More than likely, the new sensor will be damaged and cause a comeback as well.

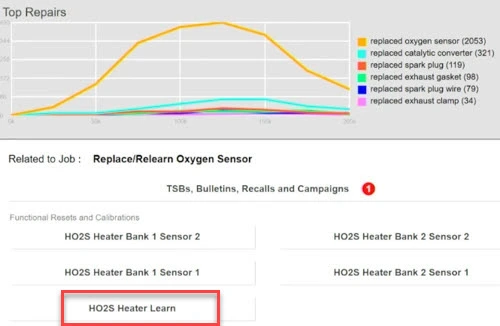

The relearn is a fast, simple procedure in the scan tool as shown below. In Top Repairs, you can also see that the O2 (oxygen) sensor is a common replaced item especially after 100,000 miles. I should ask again, how important are resets/relearns really?

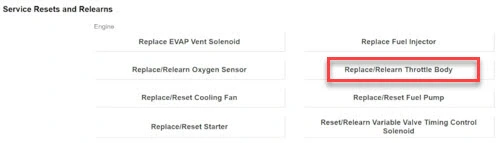

Let’s look at a 2016 Toyota® Camry® 2.5L MFI and see what resets/relearns might be important.

This vehicle has eight critical reset/relearns just on engine components alone. They are all critical because, once again, when not performed correctly a comeback or damaged components could result. A great example is Replace/Relearn Throttle Body. Toyota® says that when the throttle body is replaced or even cleaned, a relearn must be done or poor performance and possibly a check engine light could appear…comeback, right?

The poor performance complaint, reminds me of a “reset” a master certified Datsun® Technician named Bill, taught me in 1979. I was a young apprentice tech working in the bay beside him. During a tuneup, or a milage based maintenance service, I would see him grab the accerator pedal and pull back hard. I finally had to ask him; "what on earth are you doing?" He stepped over to the B210® Datsun® I was installing a radio in. He popped the air breather off and grabbed a trouble light and said “look down the carburator at the throttle plate.” He went to the drivers seat and pushed the gas pedal to the floor and said, “is the throttle plate wide open?” I said, “no, not quite”. He pulled back hard on that pedal then pressed it to the floor again, then said, “how about now?” Low and behold, the throttle plate was straight up and down, wide open. I will never forget what he said next; “I just reset the accellerator cable and linkage back to factory.” Folks, that corrected the poor performance of that B210®, just like relearning the throttle body will on this Toyota®!

Many of these resets and relearns have been necessary for years. I used to teach that when a component is replaced, a handshake was needed to introduce the new part to the PCM. If you fail to do the introductions, the PCM will not recognize the new component. That is why after repair, resets and relearns are required.

Fast Track® Intelligent Diagnostics convenietly list only the relevent resets needed for the component that has been replaced. What a great way to make sure you don’t miss this vital step!

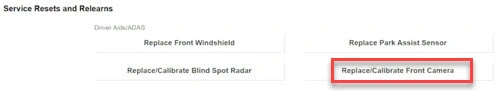

A newer system where resets and relearns are necessary, not only to prevent damaged components and reduce comebacks but maybe most importantly, to maintain safety features like ADAS (Advanced Driver Assistance Systems).

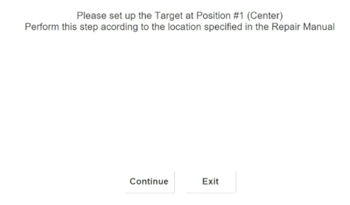

Virtually anything replaced or repaired on this system WILL need a reset. Some can be done with a Snap-on® scan tool only, and at times, a target system will be required as well.

Resets and relearns are required on the most basic repairs, such as oil changes and battery replacement. They are needed on some of the most sophisticated systems like ADAS, too. The good news is that with the right equipment and access to the proper procedures to follow, resets and relearns help us reduce comebacks, prevent component damage, and keep the occupants safe.