Fast-Track® Intelligent Diagnostics: From Codes to Confident Decisions

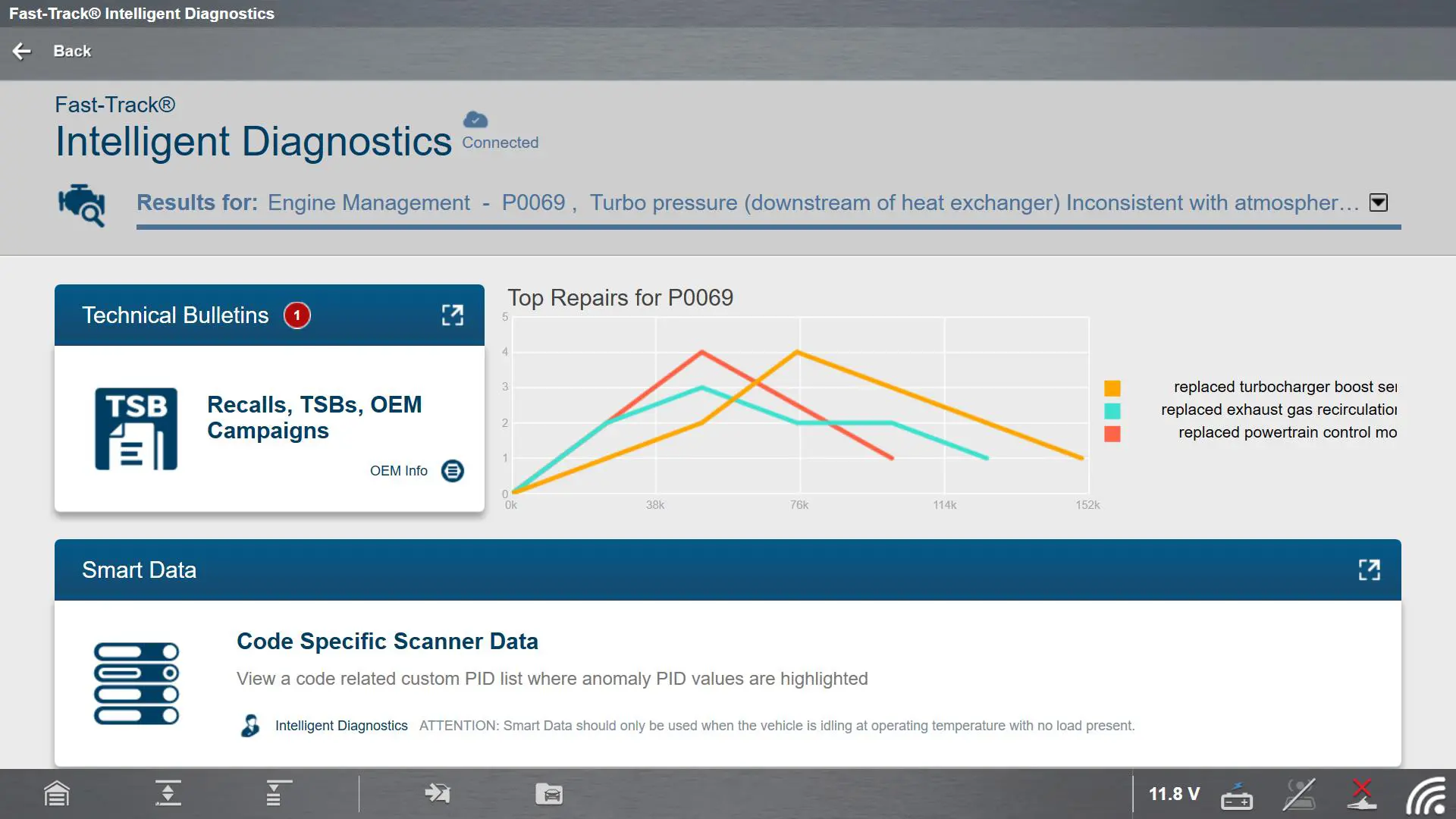

Once the pre-scan is complete, if any DTCs are found, the software displays a Diagnose button. Tap this and you’re taken directly to the Fast-Track® Intelligent Diagnostics landing page. Here’s where Snap-on® excels.

Instead of navigating through hundreds of lines of data, technical service bulletins, and possible tests, our patented Fast-Track® troubleshooting workflow with filtered information, brings focus to the specific vehicle and code you’re working on.

This includes:

- Commonly replaced parts specific to the DTC and vehicle

- Pre-filtered functional tests and technical service bulletins (TSBs) help you confirm you’re on the right path to repair

- Experienced-based information including the Top Repairs graph and verified Real Fixes show you how other techs have tackled the problem you’re facing. These verified fixes are harvested from billions of successful repair records

- Patented Smart Data automatically selects only the PIDs related to the code you are working on, and flags which ones are out of range at idle. Instead of hundreds of possible readings, we only show you the ones that matter

It’s a targeted, vehicle-specific workflow that combines complaint, cause, and correction on one page. It leads you to pinpoint the problem with the least number of steps.

Workflow That Works

The recommended diagnostic process looks like this:

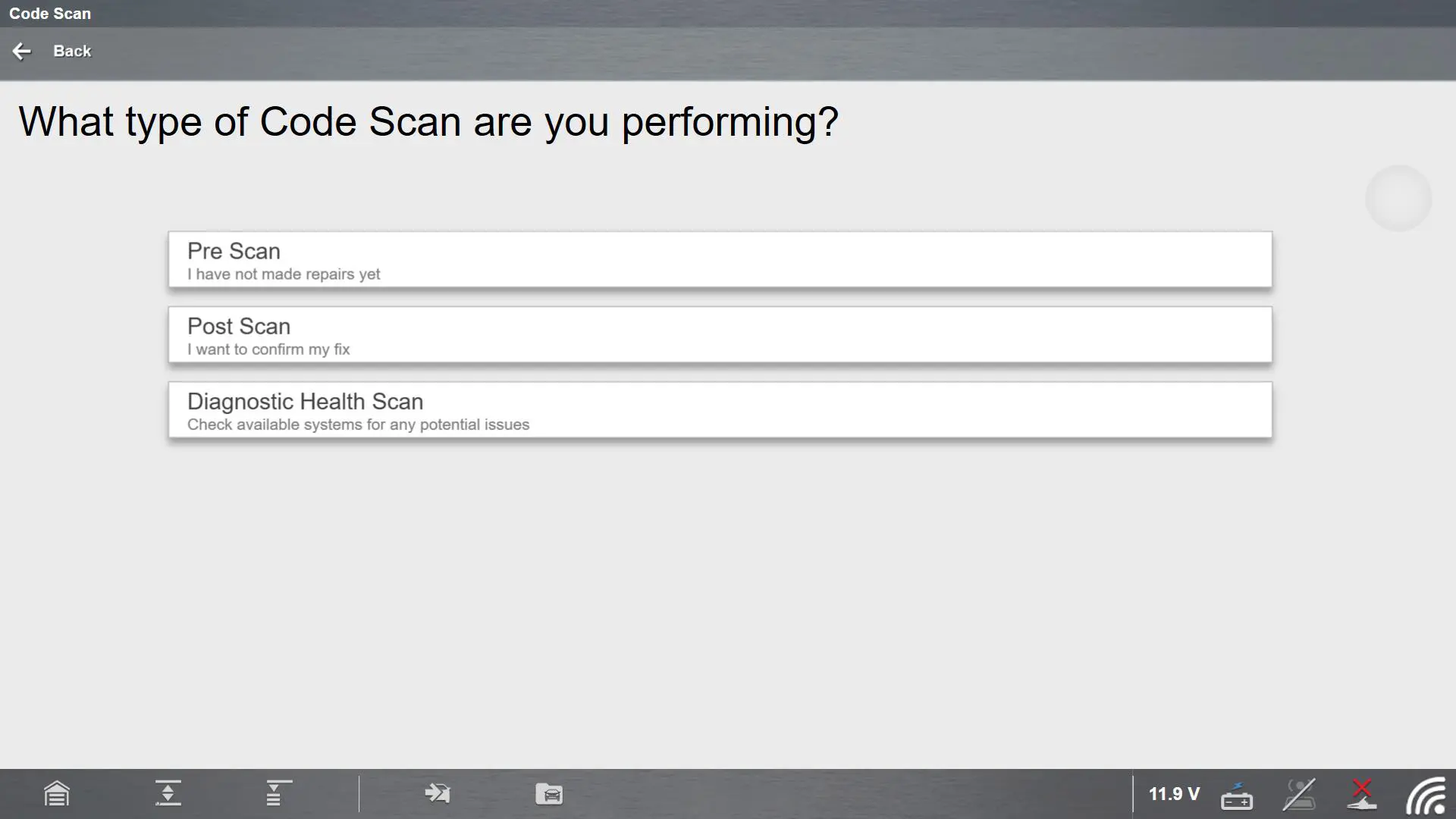

1. Pre-scan – Check all systems and log DTCs

2. Diagnose – Guided by Fast-Track® Intelligent Diagnostics

3. Test – Functional testing, Smart Data review

4. Repair – Replace or rectify the fault

5. Recalibrate – Perform necessary resets and relearns

6. Post-scan – Confirm that all systems are functioning as expected

In fact, the additional benefit of the pre-scan is that it often reveals extra work that may be needed – work that can be discussed and quoted before repairs begin. This prevents customer callbacks and ensures transparency.

Beyond the Basics

Some scan tools offer a “topology” view – a diagram of how vehicle modules are connected. While this may appear helpful, these are generic templates and don’t reflect actual module configuration or data bus layout. This can be misleading and often causes further confusion. Snap-on® software engineers chose a better route: simple, direct, accurate, no guesswork - just clear visualization and actionable results.

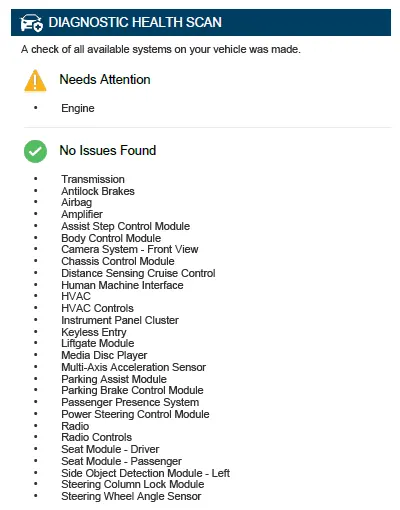

Diagnostic Health Scan- For the Workshop and the Customer

Alongside the pre- and post-scan, Snap-on® Diagnostic Software offers the exclusive Diagnostic Health Scan functionality. This provides the same comprehensive full system scan data, which is displayed in a customer-friendly report with an easy-to-understand overview that explains the vehicles condition and identifies potential issues in a simple way.

Find out more about Snap-on® Diagnostic Health Scan functionality here: