Go Beyond Scanner Data – With FAST-TRACK® Guided Component Tests Exclusively from Snap-on®

FAST-TRACK® Guided Component Tests are exclusively available on Snap-on® diagnostic tools equipped with a 2- or 4-channel oscilloscope, providing a diagnostic capability no other tool offers.

In modern vehicle diagnostics, testing individual components isn't just helpful—it’s essential. Accurately identifying whether a part is truly at fault or simply affected by another system can be the difference between a quick repair and hours of lost workshop time. Guided Component Tests help you get to the root cause of issues quickly, verify faulty parts or components, confirm repairs, and prevent costly comebacks—cutting out unnecessary trial-and-error. They also help eliminate the practice of "swapnostics"—switching out parts in the hope they fix the fault—saving valuable time and avoiding unwarranted expense.

This advanced capability goes beyond scanner data to help technicians identify the root cause of faults quickly and with confidence. FAST-TRACK® Guided Component Tests are available on: ZEUS® and TRITON™ series products as well as MODIS™ Edge and VERUS® Edge products running current software.

What Makes FAST-TRACK® Guided Component Tests Different?

FAST-TRACK® Guided Component Tests take oscilloscope diagnostics to the next level. Rather than simply displaying raw waveforms, they provide vehicle-specific test procedures that guide you—step by step—on where to connect, how to connect, and what to look for.

With over 7 million tests and built-in sample waveforms, you get the equivalent of on-the-job training every time you use it—reducing guesswork and increasing diagnostic certainty. It’s this combination of instruction, automation and insight that transforms a traditional scope test into a highly efficient diagnostic workflow.

Why Component Testing is Important?

Scanner data is invaluable, but it's only part of the story. A scanner tells you the effect—what the vehicle systems are experiencing. But to uncover the cause, you need to test the component or circuit directly. Guided Component Tests bridge the gap by verifying suspected faults in real time, helping to:

- Avoid unnecessary parts replacement

- Reduce comebacks and improve customer satisfaction

- Gain confidence before ordering and fitting parts

Whether the fault is an open, short, or resistance issue in the circuit, Guided Component Tests help you pinpoint the failure with clarity.

Why Guided Component Tests are Unique on Hybrid Vehicles?

Snap-on’s Guided Component Tests deliver hybrid vehicle diagnostics that extend far beyond conventional oscilloscope testing. Working on hybrids requires a unique approach, prioritising safety, specialised knowledge, and precise testing.

These tests provide built-in safety training, hybrid-specific procedures, and real-time Smart Data that flags spec values. From unfamiliar terminology to essential resets like battery current sensor initialisation, technicians gain the confidence and clarity to diagnose and repair hybrid systems accurately and efficiently.

Procedures for Hybrids are required because:

- Because of complex electronics involved, diagnosing hybrid vehicles is typically carried out using a scanner.

- High voltages require caution when working on hybrid components always ensuring safety at all times.

- 12-volt systems, however, can be diagnosed similarly to conventional vehicles, using familiar methods and tools.

- Caution: Most high-voltage systems are not suitable for testing with a traditional automotive oscilloscope due to safety risks and system complexity.

Working on hybrid vehicles presents different challenges compared to traditional petrol or diesel models—and safety must always come first. For those less experienced with hybrids, Snap-on® diagnostic tools provide built-in topical training classes directly on the tool, giving the confidence to take on repairs (including those on EV and Hybrid Systems).

You could call it “school in the tool”—and it starts with safety.

Caution: EV and Hybrid training is an essential qualification required prior to conducting any repair work on an EV or Hybrid vehicle!

Safety First: Training Strongly Recommended for High-Voltage Systems

Working on electric and hybrid vehicles involves high-voltage systems that demand specialist knowledge and strict safety procedures. Formal training is strongly recommended to ensure safe, accurate diagnostics and repairs.

Requirements may vary depending on your location, so it's important to check with your local regulatory body or industry authority to confirm any applicable standards or certifications.

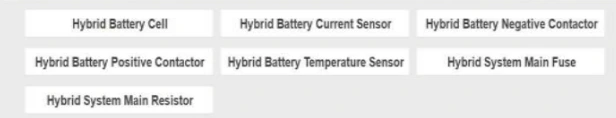

Additional Hybrid Systems

There are many additional systems in a hybrid vehicle in addition to the conventional combustion systems. These can include:

- Electric motor (Most are 3-phase 500v+ AC)

- Resolver

- Battery heating system

- Lithium-ion polymer battery

- Voltage converter

- Regenerative braking system

- Charging system

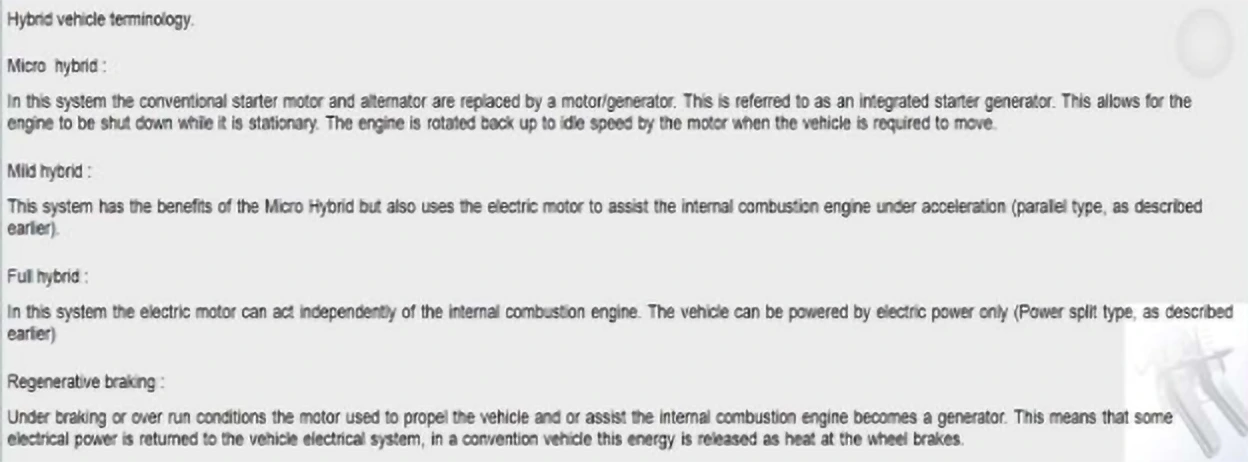

Hybrid Terminology Explained

Even the terminology used in hybrid diagnostics differs from conventional vehicles. That’s why Snap-on® Diagnostic Tools include classes that explain key concepts and language—so you're not left guessing.

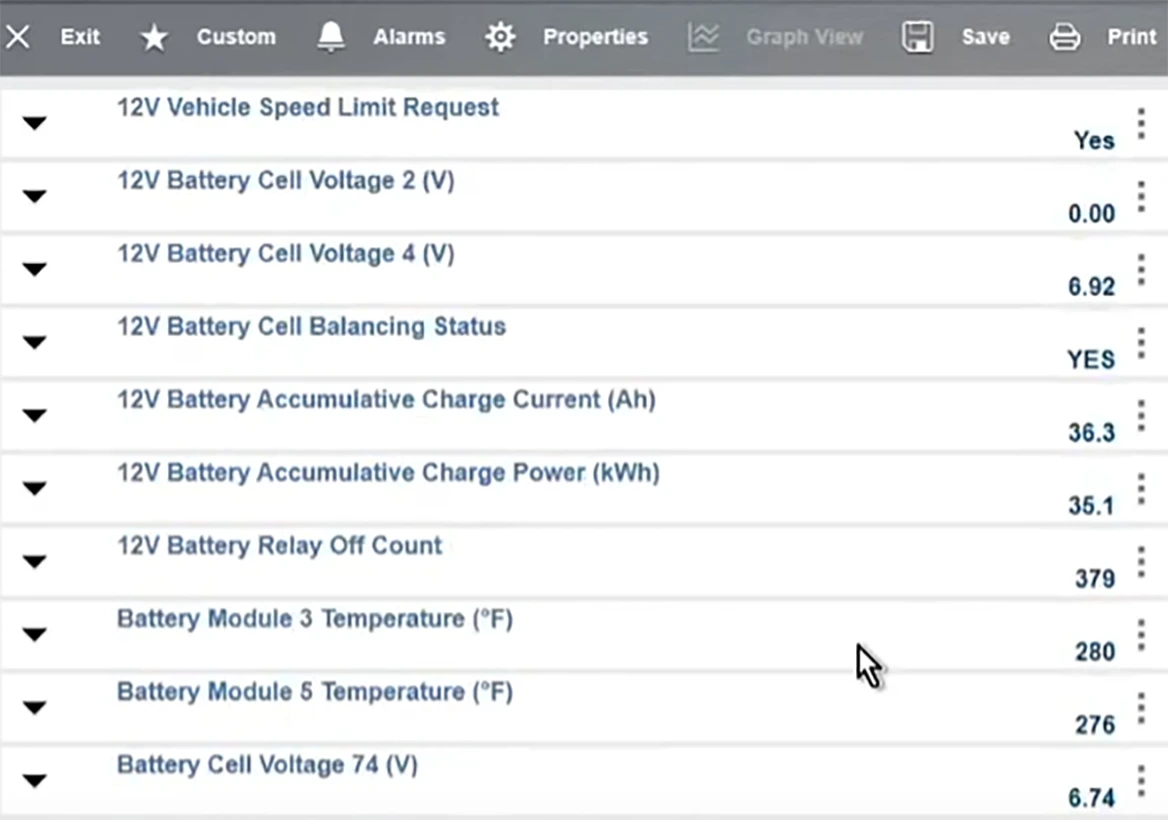

Dedicated Hybrid Data Lists & Diagnostic Support

When you're working on the gasoline side of a hybrid, many systems will feel familiar. But diagnosing hybrid-specific systems requires special data, tests, and training. These Guided Component Tests offer:

- Custom data lists for hybrid subsystems

- Battery-related data, including cell voltages and temperature sensors

- Control unit and charger diagnostics

- Built-in Smart Data, which highlights out-of-spec PIDs in real time using min/max values—making fault detection much quicker

Case Study: 2009 Toyota® Prius® with DTC P0AC0

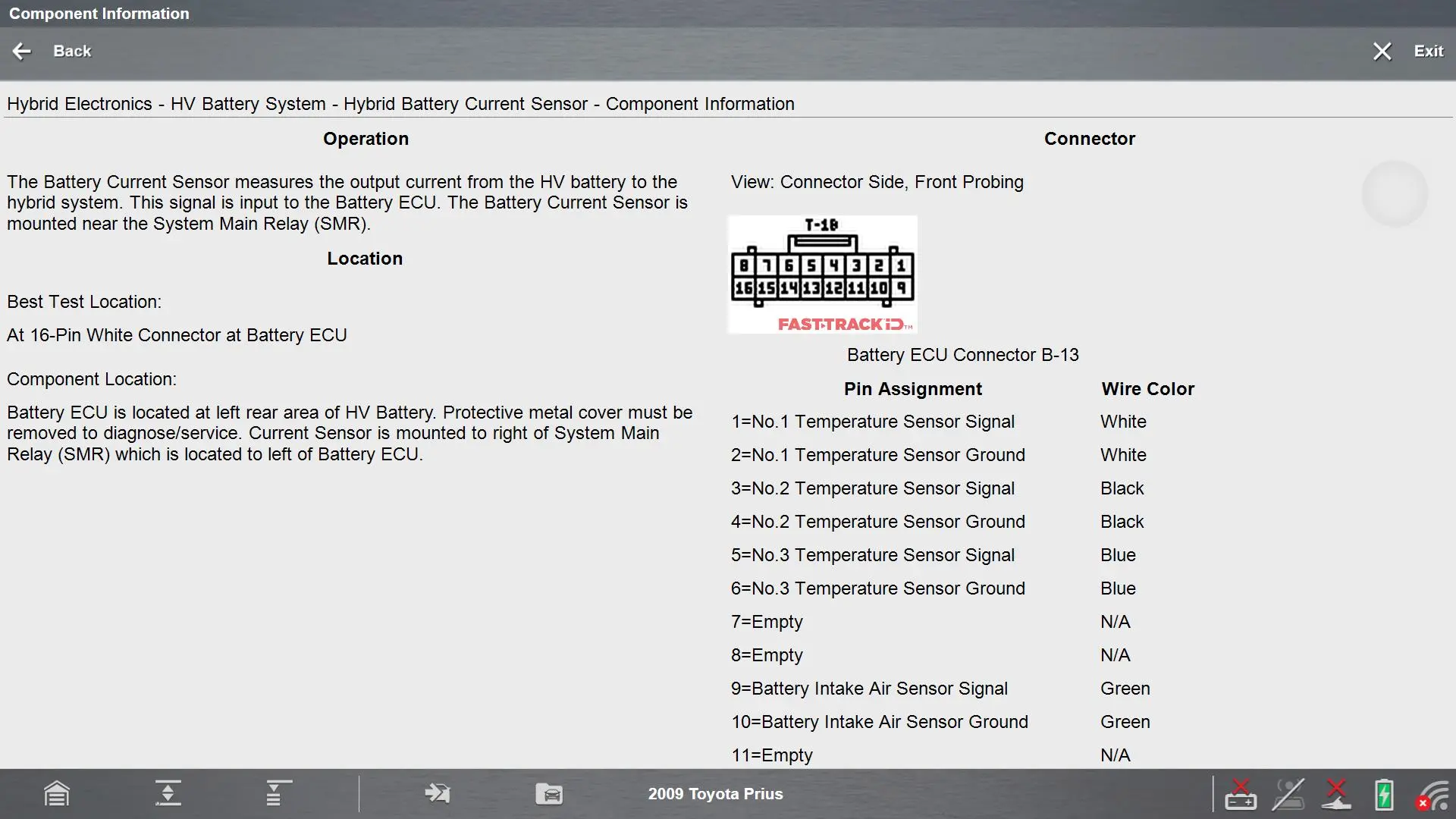

In one real-world case, a Toyota® Prius® presented with a P0AC0 – Battery Current Sensor Circuit fault. Guided Component Tests walked the technician through:

- How the circuit and sensor operate

- Where to connect for accurate testing

- What the signal should look like on a scope or multimeter

The test confirmed the vehicle’s battery current sensor was faulty. The sensor was replaced—but the job didn’t end there.

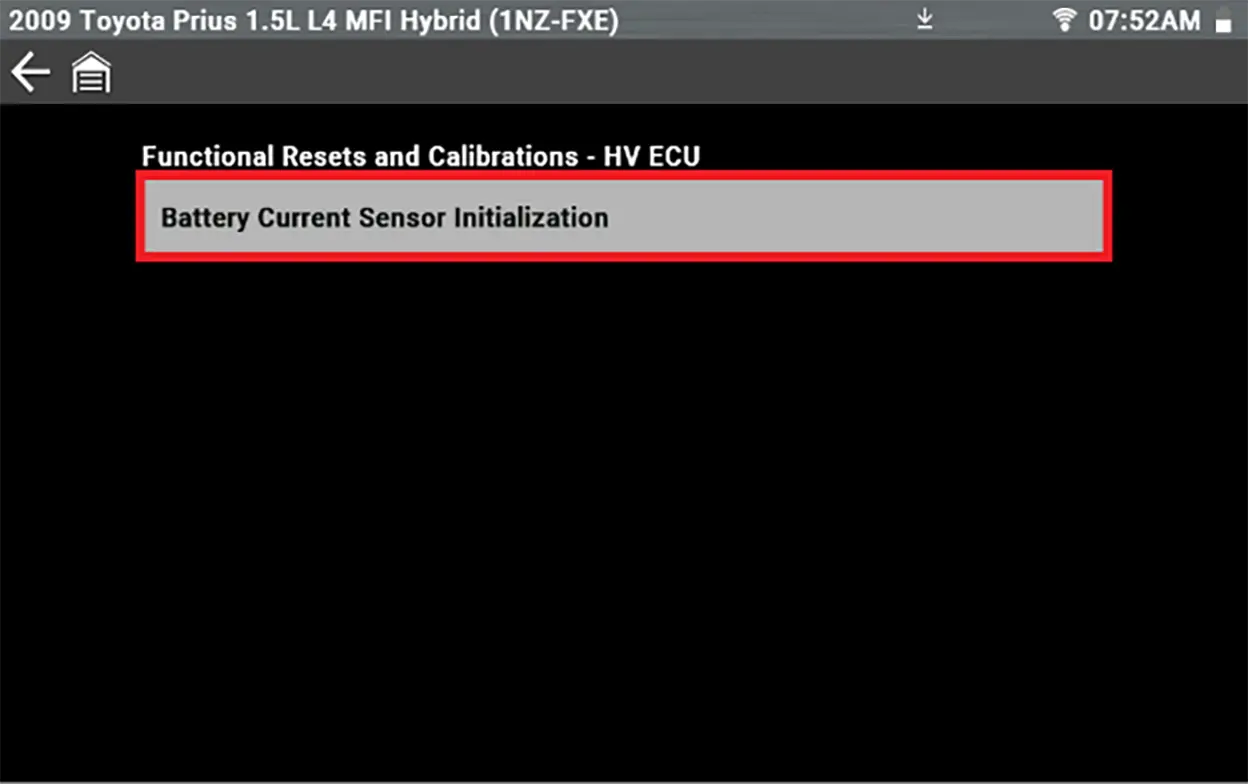

Essential Reset: Battery Current Sensor Initialization

Once the new sensor was installed, the tool guided the technician through a Battery Current Sensor Initialization—a crucial step that recalibrates the sensor with the hybrid ECU. Without it, the charging system wouldn’t function correctly.

![Battery Current Sensor Initialisation Procedure]](/Files/Diagnostics-US-2020/News-Center/2025/Software-Landing-Pages/May-25-Guided-Component-Tests/Service-Reset-and-Relearns.webp)

Result: Repair confirmed, vehicle charging correctly, job complete.

See the Difference in Every Diagnosis

Each guided component test is more than just a walkthrough—it’s an expert-led diagnostic session:

- Scope setup is simplified with clear vehicle-specific instructions

- Connector locations and test points are illustrated

- Sample waveforms show what a “know-good” and “known-bad” signal will look like

- Live comparison between your capture and reference waveforms

- Advanced tips, including fused jumper techniques when components are hard to access

It’s everything you need to complete the test accurately and quickly.