This article aims to provide a comprehensive overview of DPF system design, history, regeneration strategies, diagnostic procedures, and fault handling. It is intended to support accurate diagnosis, avoid missed steps in forced regeneration or resets, and ensure component integrity across the emission control systems.

Can I hear someone yelling at the DPF warning light, again?

With the widespread adoption of diesel particulate filters (DPF) in modern diesel-powered vehicles, technicians are increasingly faced with DPF-related faults, customer complaints and costly repair procedures for the customer. In many cases, the vehicle owner wasn’t aware of the operational needs of DPF systems, particularly in vehicles used for short, low-speed trips. Those vehicles never reach ideal regeneration conditions to regenerate the particle filter and stop soot build-up in the DPF.

The History of the DPF

In the early 2000s, some high-end or eco-focused diesel models began using DPFs, particularly in Europe. Certain manufacturers, especially premium German brands, offered them ahead of legislation to reduce visible smoke and meet internal green targets. Diesel particulate filters made their entrance into the U.S. market primarily due to tightening EPA emissions regulations, with a strong focus on reducing particulate matter (PM) and nitrogen oxides (NOx) in the mid-2000s.

- Pre-2005: Limited use in high-end European diesels for smoke reduction and eco-branding.

- 2007: In the U.S, DPFs became mandatory for heavy-duty trucks.

- 2008–2010: The U.S adopted DFPs in light-duty diesel pickups and SUVs.

- 2010: It becomes standard in diesel passenger cars and crossovers, combined with SCR systems in the U.S.

Principles of the DPF System

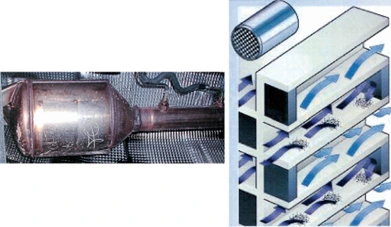

The DPF is constructed from a ceramic monolith, coated with precious metals such as platinum. Its internal structure resembles a catalytic converter but features alternating blocked channels, forcing exhaust gas through porous walls where particulates are trapped. Surface area equivalents often exceed three football fields, allowing for high filtration efficiency.

ECU Inputs to Trigger a Regeneration

• Multiple exhaust Temperature sensors

• DPF differential pressure sensor

• NOx sensors

• Airflow and ambient air sensors, which are sometimes in the wing mirror

• Oil condition sensor

• Glow plugs

• EGR valve

• Fuel injectors

• Variable geometry turbo (VGT) and manifold absolute pressure sensor (MAP)

• DEF Diesel exhaust fluid (DEF) system

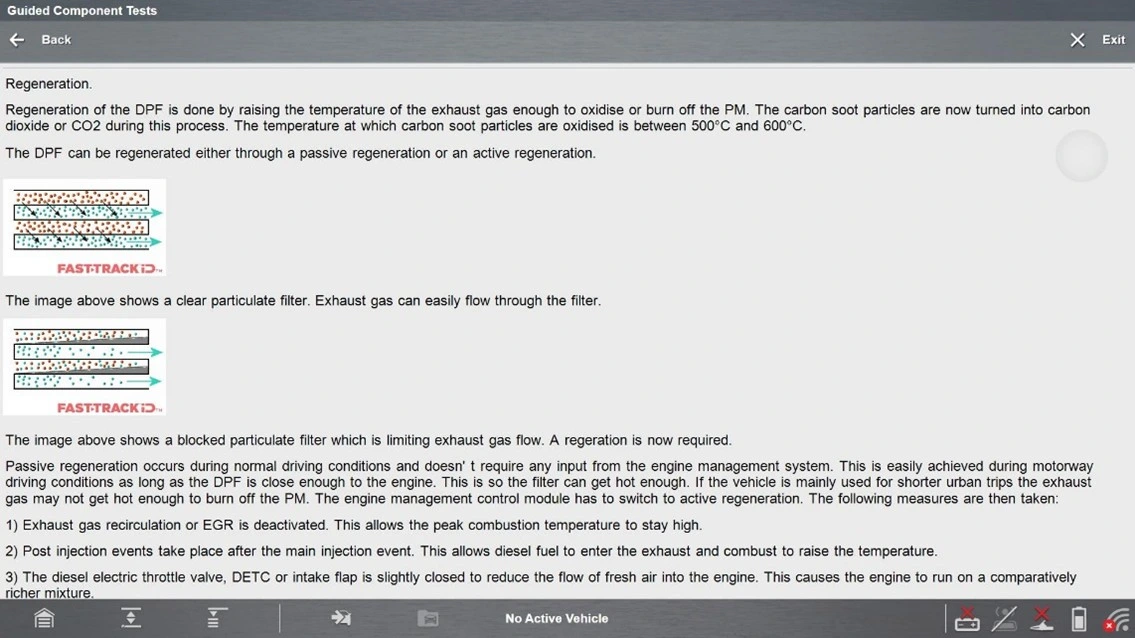

Different DPF Regeneration Processes

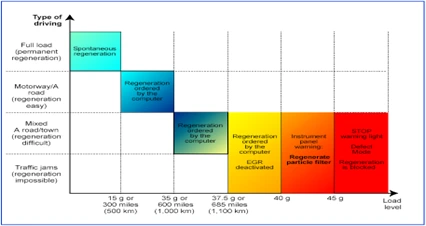

The primary reason for soot removal is to prevent the buildup of exhaust back pressure. Excessive back pressure increases fuel consumption, reduces power output and can potentially cause engine damage. Several factors can trigger the diesel PCM to perform regeneration, including distance since last DPF regeneration, fuel used since last DPF regeneration, engine run time since last DPF regeneration and exhaust differential pressure across the DPF.

There are several ways to perform a DPF Regeneration:

Passive Regeneration

• Occurs under continuous driving with high exhaust temperatures (motorway/highway operation).

• Requires no ECU intervention

Active Regeneration

- Commanded by the PCM when the excess soot build-up thresholds are met

- During regeneration, the exhaust gases reach temperatures above 550°C (1000°F).

- Requires:

- Minimum vehicle speed (typically >30 mph)

- Extended drive duration (20–30 mins)

- No system faults

- At least ¾ tank of fuel

Forced Regeneration

• Initiated via scan tool

• Requires full system readiness (see next section)

• Must only be performed under correct preconditions

Regeneration Preconditions and Fault Dependencies

With any type of regeneration, if any of the following systems or sensors are compromised, regeneration will fail:

• Faulty glow plugs

• Inoperative or leaking EGR system

• Incorrect fuel injection calibration

• Sticking VGT or wastegate control

• Malfunctioning ambient air sensor

• Oil degradation beyond the threshold

• AdBlue® system faults or low-DEF levels

• DPF pressure sensor deviation

• Exhaust temperature sensors out of range

• Fuel level below threshold (¾ of a tank)

Note: Even with a scan tool, initiating forced regeneration without meeting these criteria can cause thermal overload, catalyst damage or result in incomplete burn cycles. Make sure you have checked using component testing before you perform the DPF Regeneration.

Case study: Read how a fault in a Ford Focus's diesel particulate filter sensor was diagnosed, repaired and verified using a diagnostic platform from Snap-on here.

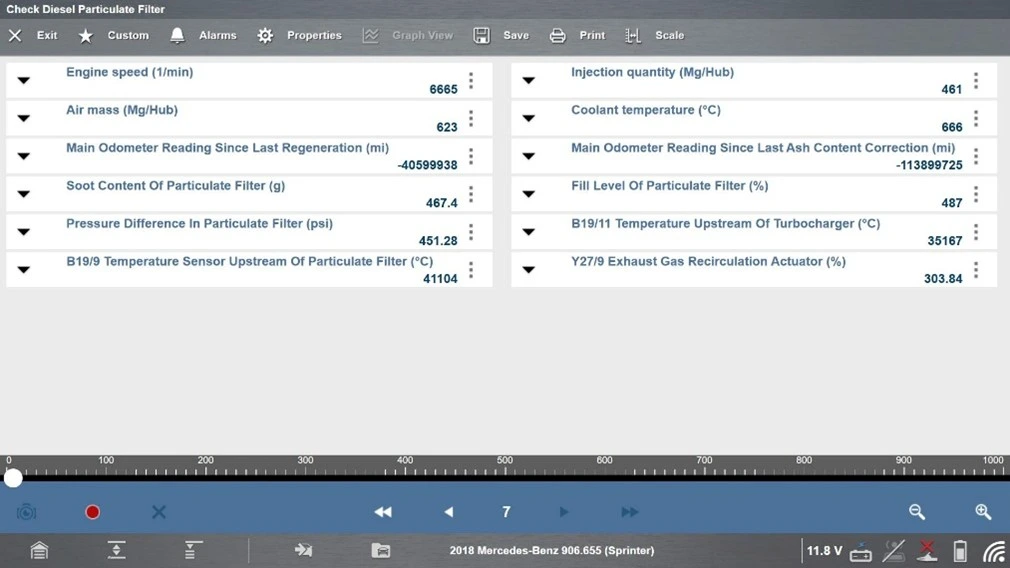

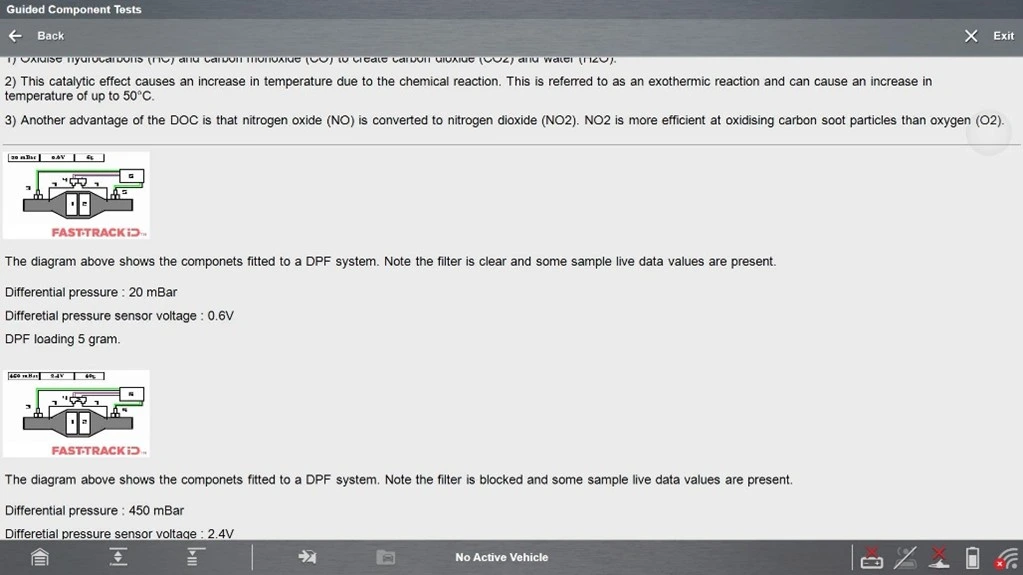

DPF Pressure Values

Using your scan tool, check Live data and perform the DPF Pressure test. Refer to ShopKey® for normal pressure values.

Normal Differential Pressure (Approx. values):

• Idle: 2–10 millibar

• 3000 RPM (no load): 30–40 millibar

Always compare against OEM-specific values. Variations exist across platforms including PSA Group®, VW®, Ford®, BMW®.

Conversion Table (if OEM reports in different units):

• 1000 millibars = 15psi at sea level, approximately

• 69 millibar = 6.9 kPa

Warning: if the pressure is zero or abnormally low, suspect a collapsed DPF core or bypass crack. Confirm by checking for excessive soot in the tailpipe.

DPF Reset and Soot Relearn – When to Avoid

Never force the relearn of soot values or reset the DPF system to initialise unless:

• The filter has been physically cleaned or replaced

• All system components are functioning correctly

• Pressures are within the allowable OEM range

Incorrect resets under fault conditions can:

• Cause severe engine overloading

• Damage the oxidation catalyst

• Trigger permanent PCM DTCs

• Lead to warranty rejection or recall flags in dealer diagnostics

How SCR and AdBlue® Systems Affect a DPF Regeneration

In modern diesel engines, Selective Catalytic Reduction (SCR) and the Diesel Particulate Filter (DPF) work together as part of a multi-stage emissions control system, but they perform different functions and are located at different points in the exhaust flow.

All systems (DOC, DPF, DEF, SCR) are monitored and controlled by the engine control unit (ECU). It uses data from:

• NOx sensors (pre and post SCR)

• DPF differential pressure sensors

• Exhaust temperature sensors

• DEF quality and level sensors

If anything is out of specification, it can:

• Trigger regeneration

• Adjust DEF dosing

• Log DTCs

• Derate or disable engine start (if emissions compliance is violated)

Selective catalytic reduction (SCR) is standard in nearly all modern diesel vehicles, including heavy-duty trucks, light-duty pick-ups, SUVs and cars. Selective catalytic reduction (SCR) is a method used to reduce NOx emissions by injecting urea into the exhaust stream. Instead of using large amounts of exhaust gas recirculation (EGR), the SCR system uses urea. Urea is used as a nitrogen fertilizer. It is colorless, odorless and nontoxic. Urea is called diesel exhaust fluid (DEF) in North America.

Learn While You Work: Built-In Diesel Emissions Training

The Snap-on ZEUS™ , VERUS™ and TRITON™ diagnostic platform families are powerful, with training tools built to increase technician confidence and capability right at the vehicle. These platforms include on-tool training classes, covering everything from DPF and SCR system operations to component testing and live data interpretation and much more.

Figure: 15 Minute Selective Catalytic Reduction Class

Figure: 20 Minute Diesel Particulate Class

Conclusion

• Always validate sensor signals via live data before proceeding with regen or resets.

• Perform regular DPF pressure trend checks as part of diesel service routines.

• Educate customers about the importance of high-speed runs for passive regeneration, especially in urban-use vehicles.

For a deeper dive, explore our comprehensive guide on DPF regeneration: how it works and why it’s necessary. You can also read our latest software exclusive article on mastering diesel functional tests with Snap-on® Diagnostic Software.