Evaporative Emission Control (EVAP) systems are a critical component of modern vehicles, preventing fuel vapours from escaping into the atmosphere. Faults in the system not only trigger diagnostic trouble codes but can also lead to comebacks and reduced workshop efficiency.

With the latest Snap-on® Diagnostic Software and tools, technicians can access Fast-Track® Guided Component Tests, troubleshoot using real-world tips, and perform vehicle-specific tests, including the exclusive Evaporative Emission Canister Purge Valve Leak Test.

EVAP System Overview: Key Components and Functions

The EVAP system is composed of multiple interdependent components that work together to capture and control fuel vapours. Understanding each part is essential for accurate diagnostics.

Purge Solenoid

The purge solenoid controls the flow of vapors into the intake manifold. Many vehicles use a pulse-width modulated solenoid, which allows precise control over vapor flow. The purge solenoid also plays a role during leak testing and is a common repair item when faults are identified.

Vent Valve

The vent valve operates as an electronic on/off solenoid. It allows filtered air into the canister under normal operation and closes during leak testing to seal the system. Blockages or contamination in the vent valve can prevent the tank from refilling correctly and are a common cause of EVAP-related customer complaints. In some designs, the vent valve is integrated with the canister for compact assembly.

Canister

The canister stores fuel vapors in activated charcoal and may include electrical components in more advanced systems.

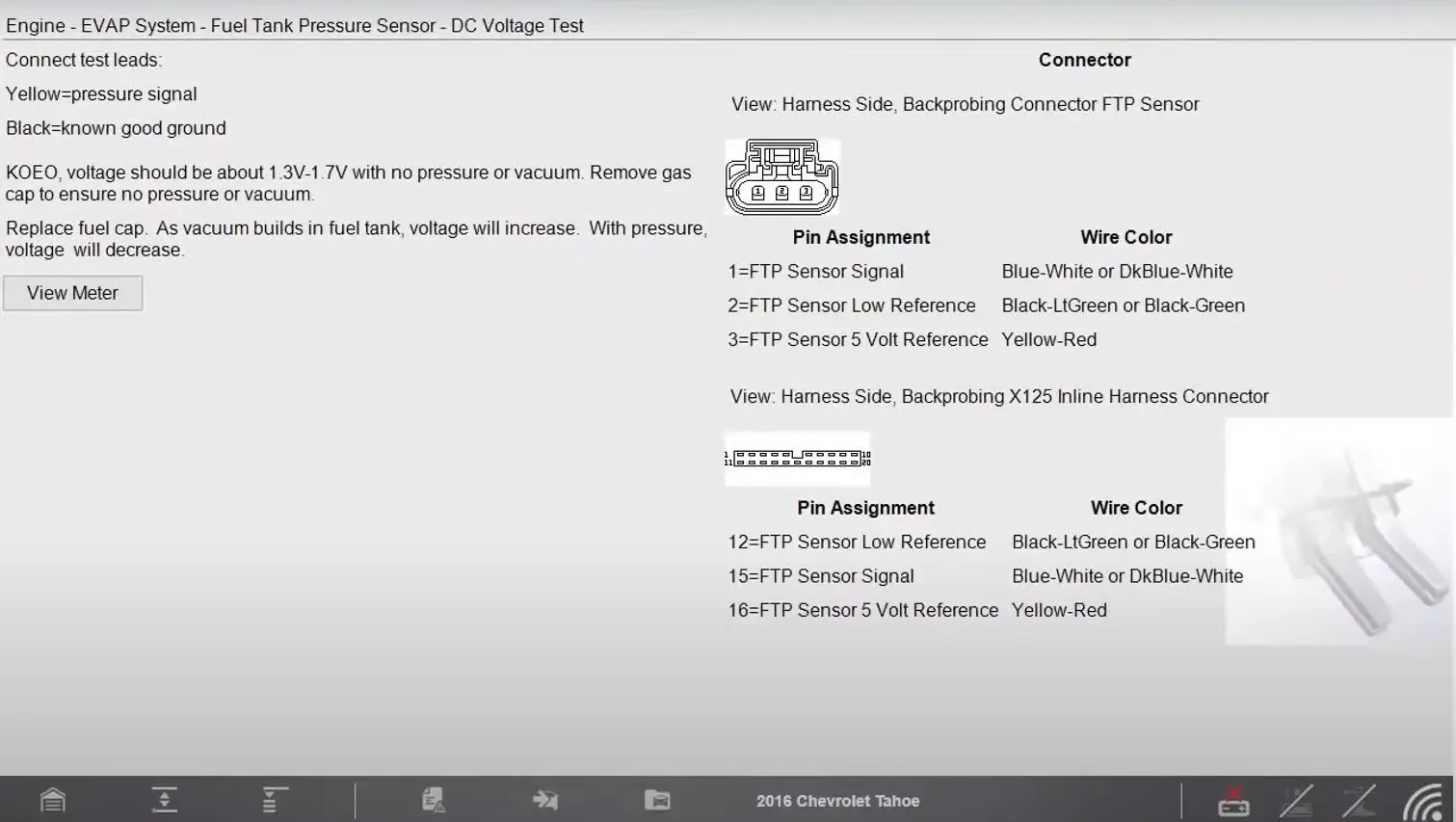

Fuel Tank Pressure Sensor

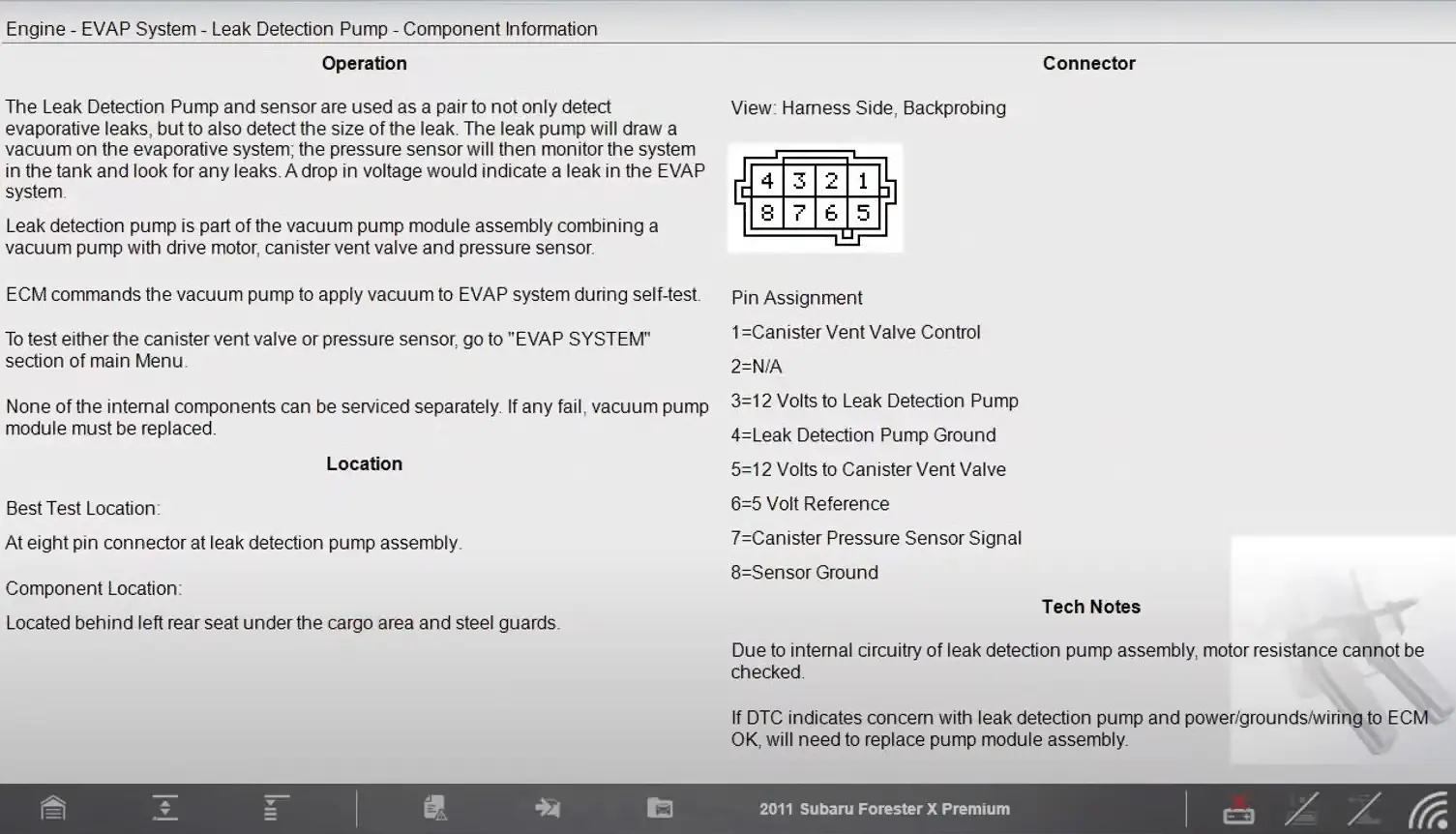

The fuel tank pressure sensor monitors tank pressure and outputs a voltage proportional to the vacuum or pressure. Typically a three-wire sensor, it provides a 5V reference, a signal, and a ground. Accurate readings from this sensor are critical for leak detection.

Leak Detection Devices

Leak detection devices such as NVLD, ESIM, and DMTL automate vacuum or pressure-based leak detection. The ECM commands the vacuum or pressure pump to pressurise the system, and voltage or amperage feedback determines the size of any leak. A drop in amperage can indicate a large leak, while higher-than-reference amperage indicates no leak.

Fast-Track Guided Component Tests

Snap-on® Fast-Track Guided Component Tests provide step-by-step instructions for every EVAP component, including hookup points, expected readings, and testing tips. These procedures remove guesswork, guide technicians efficiently, and are invaluable for complex systems like BMW DMTL or ESIM, where solenoids, pumps, and sensors interact.

2017 Subaru Forester X Premium, EVAP Leak Detection Pump - Component Information

2016 Chevrolet Tahoe Fuel Tank Pressure Sensor – DC Voltage Test

BMW DMTL and the ESIM (Evaporative System Integrity Monitor)

BMW uses the DMTL (Diagnostic Module Tank Leakage) pump to check EVAP system integrity. At rest, fresh air flows through the sprung-open pump valve. During a leak test, the DME activates the pump, which pushes air through a restrictor; the resulting amperage is compared to reference values to assess system integrity. The solenoid valve then seals the system, and the amperage draw indicates the presence and size of any leak.

Leak detection results:

For example, you can perform the EVAP Tank Leakage Diagnosis (DMTL) Functional Test on your Snap-on® tool, as shown in the screenshot below from the 2010 BMW 335i.

2010 BMW 335i Functional Tests

How the EVAP System Operates

To understand EVAP operation, picture the purge valve as the front door and the vent valve as the back door.

-

Normal operation – The vent valve (back door) remains open to allow fresh air circulation, while the purge valve (front door) stays closed. This prevents pressure build-up during refuelling. If the vent valve becomes obstructed, the tank cannot vent properly during filling, restricting fuel flow and triggering customer complaints.

-

Vapor storage and purging – As fuel is added, vapors are directed into the charcoal canister for storage. Once the engine reaches operating temperature, the purge valve opens, creating a vacuum that draws fresh air in and displaces stored vapors into the intake manifold to be combusted.

-

Leak testing – Both valves close, and vacuum is applied, either from a leak detection pump, or using engine vacuum. The fuel tank pressure sensor monitors changes: if the system holds, it’s sealed; if pressure drops, the ECM calculates the leak size and sets a corresponding DTC.

Common EVAP DTCs

⚠️ Not all EVAP codes indicate a leak. Codes like P0443 or P0446 point to electrical faults in solenoids or circuits. Correct interpretation of the code is critical to avoid misdiagnosis.

Testing Methods

-

Electrical testing – With a scan tool, you can activate purge and vent valves, monitor sensor responses, and confirm whether the system seals correctly under command.

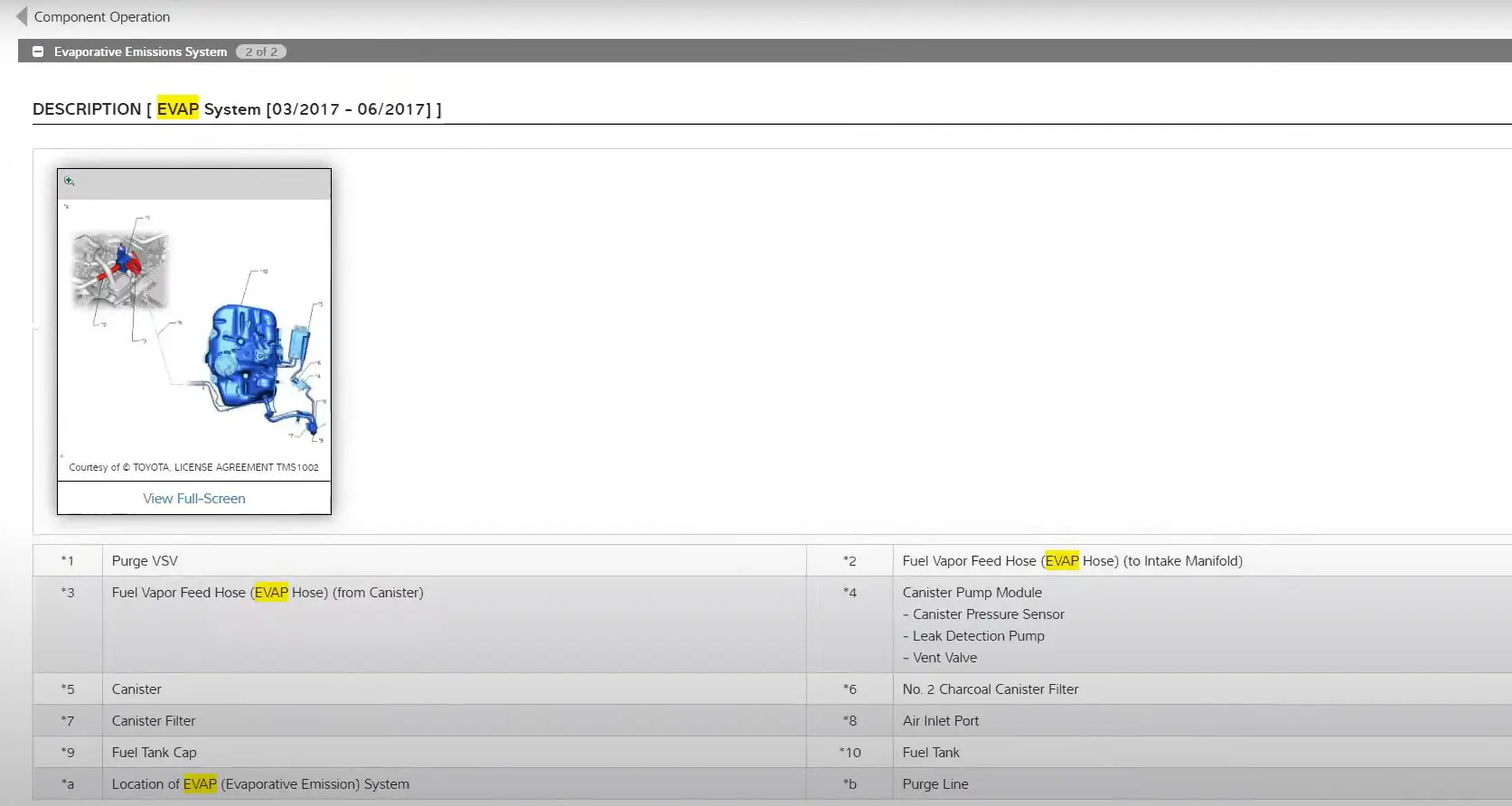

Practical real-world examples, such as the Toyota EVAP purge solenoid test, show how these methods integrate seamlessly with Snap-on® diagnostics to streamline the path from fault to confirmed fix.

Real-World Example: Toyota EVAP Purge Solenoid Test:

Case Study - Toyota EVAP Purge Solenoid Test: Operational Procedure

-

Select: Service Resets and Relearns > Replace EVAP Purge Solenoid.

-

The tool automatically checks OEM recalls, TSBs, and campaigns relevant to this job.

-

If you have a ShopKey® Pro subscription, link directly to repair information from within the tool.

-

Select: EVAP purge solenoid replace.

-

Choose: Remove and replace to view the OEM repair procedure.

-

Return to Scanner and select: Functional Resets and Calibrations.

-

Select: Activate the EVAP Purge VSV.

-

Follow onscreen instructions to complete the procedure.

-

Cycle the control from OFF to ON and confirm solenoid operation.

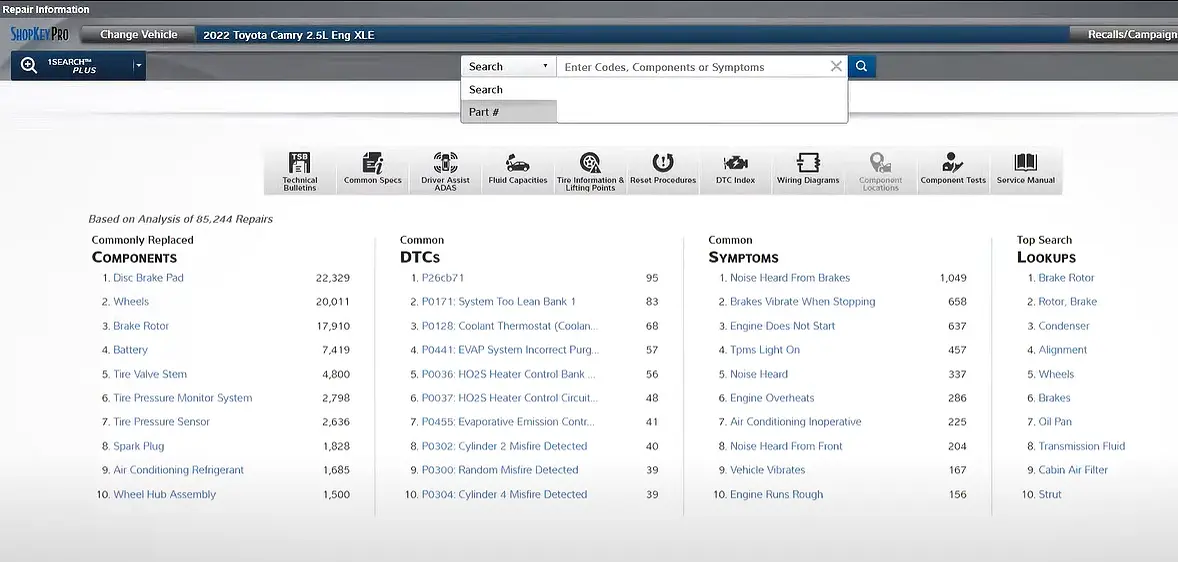

With the purge solenoid test complete, you can now review supporting data to validate the results. Using ShopKey® Pro, you’ll have instant access to component details, diagrams, and real-world repair records, helping you confirm your findings before moving on to electrical verification.

Electrical Verification – Most EVAP components use simple on/off solenoids or three-wire sensors, making them straightforward to test with the right data.

ShopKey® Pro results for 2022 Toyota Camry XLE – based on over 85,000 repair records. Requires a current Snap-on® Diagnostic Software and a ShopKey® Pro Information System Subscription

Detailed information on component operations including location diagrams and component information and use hints.

Common Failures and Real-World Examples

EVAP system failures can be varied and sometimes obscure, but Snap-on® Diagnostic Software streamlines the path to the fix with certainty.

Vehicle: Mazda® 6 vehicles with the 2.5L engine (14 Sept 2009 – 2 May 2011)

Case Study: Cadillac CT4 EVAP Purge Valve Leak Test

Snap-on® Diagnostic Software continues to expand EVAP coverage, now including the Evaporative Emission Canister Purge Valve Leak Test on the 2024 Cadillac CT4. This targeted test makes it quicker and simpler to confirm purge valve integrity—one of the most common causes of EVAP-related comebacks.

2024 Cadillac CT4 – Purge Valve Leak Test Procedure

-

From the Vehicle Systems Menu, select Engine.

-

Navigate to Functional Tests.

-

Choose Evaporative Emission Canister Purge Valve Leak Test.

-

Select either Venting (open) or Not Venting (closed).

-

The software holds the valve in the selected state for 30 seconds.

-

Review the result — test complete.

EVAP System Diagnostics Made Easy with Snap-on® Diagnostic Software

EVAP system diagnostics can be one of the most challenging areas for technicians, with leaks, purge valve faults, and vent valve failures frequently leading to repeat visits. By combining a solid understanding of system operation with the latest Snap-on® Diagnostic Software, technicians gain the tools to simplify the process, from Guided Component Tests and Troubleshooter Tips to automated PID baselines and exclusive functionality like the Evaporative Emission Canister Purge Valve Leak Test.

The result is faster, more accurate fault identification, reduced risk of misdiagnosis, and greater workshop efficiency. With EVAP problems ranking among the most common issues in modern vehicles, having reliable workflows and expanded coverage ensures you can approach every job with confidence, deliver a first-time fix, and prevent comebacks. You can view our online vehicle coverage guide here.

FAQs

What is the most common cause of EVAP system faults?

Leaking purge valves and contaminated vent valves are the most frequent causes in modern systems. Blocked vent lines can also create negative fuel tank pressure and refuelling issues.

How can I differentiate between a small leak and a purge valve fault?

A purge valve slightly stuck open can mimic a small system leak. The dedicated Evaporative Emission Canister Purge Valve Leak Test in Snap-on® software confirms whether the valve seals properly.

Why is the vent valve so prone to failure?

Being located low on the vehicle, the vent valve is exposed to dust, debris, moisture, and road salt. Blockages or corrosion can prevent sealing during leak tests or restrict airflow during refuelling.

What is the fastest way to detect EVAP leaks?

A smoke machine, such as the Snap-on® Smart Smoke® EVAP Machine, allows you to visualise leaks instantly and pinpoint cracked hoses, faulty seals, or blocked lines that are otherwise invisible.

Do all EVAP-related codes indicate a leak?

No. Codes like P0443 (purge solenoid electrical fault) or P0446 (vent control electrical issue) indicate electrical or circuit faults rather than leaks. Correct interpretation prevents wasted diagnostic time.

How do Snap-on® Guided Component Tests help with EVAP diagnostics?

They provide step-by-step instructions, hookup diagrams, and known-good waveforms for purge valves, vent valves, pressure sensors, and leak detection pumps—removing guesswork and speeding up diagnostics.

What’s the benefit of using Troubleshooter Tips for EVAP faults?

They draw on thousands of real-world repairs to highlight common failure points such as cracked filler necks or contaminated vent valves. Mileage-based graphs show which parts and procedures have successfully resolved the issue.

Can EVAP issues affect engine performance?

Yes. Faulty purge or vent valves can create vacuum leaks or fuel-lean conditions, which may trigger drivability issues, reduced fuel efficiency, or check engine lights.

Should I replace the entire EVAP canister if there’s a vent blockage?

Not always. Many blockages can be cleared by cleaning or replacing the vent valve or line. Snap-on® Guided Component Tests help identify exactly which component is at fault, avoiding unnecessary parts replacement.