Meet Clint and Hayden Aleshire, father son duo from Texas. Clint is a seasoned store manager with Dean Akin Tool Company and a devoted family man. Hayden is his youngest son and assistant store manager. The family picture shows, left to right: Hayden, Gaven (USAF), Amber, Clint and Ethan.

This amazing father and son team service the Baytown and Anahuac areas of Texas.

At kickoff this year, Clint and Hayden received the coveted 18 FTA (First Time Activation) Award in recognition of a fantastic 2022. Actually, they had achieved well over the 18 FTAs. They decided that very night that they were going to be NUMBER ONE in FTAs in their group for 2023. At the same time, they set a goal to average more than $30,000 in paid sales per week.

So far, they are well above that FTA goal with 15 year to date. They are not only number one in their FPT, but are number two in North America for FTAs. It looks like they are well on their way to achieving their goals.

The FTAs include a nice mix of platforms with SOLUS Legend™, APOLLO-D9™, TRITON-D10™, ZEUS+™ and workstations. Actually, the majority of these FTAs were on the higher-end platforms.

When asked "What are you and Hayden doing to be so successful with so many FTAs already?" Without hesitation Clint said, “We believe there should be a Snap-on® scan tool in every tool box — we intend to make that a reality in our route”.

How long has Hayden been learning the business? He has been working with dad since he was a little boy. He would spend all day in the store watching, listening and learning features/benefits, and of course, sales techniques. Clint has been grooming Hayden to drive and develop the diagnostic segment of the business. Just last week (3/13/23), Hayden sold a customer the TRITON-D10 by demonstrating the features and benefits of the Guided Component Test and Lab Scope. Clint proudly stated that his son handled the entire deal from start to finish with no assistance from him.

So the big question — what exactly are you doing to achieve your quest to have a Snap-on diagnostic tool in every tool box in your route?

OPPORTUNITY LIST

Clint states that they start each week by researching the opportunity list with customers that are nearing end of life. With newer technology platforms available, they also look for customers with legacy tools, like VERUS®, MODIS™ or SOLUS Edge™. They are prime trade up prospects.

PRE-LIST

They review the pre-list for customers who do not own their own tool (this is discovered by simply asking what scan tool do they use).

ROI CALCULATOR

We show customers the ROI calculator using their diagnostic rate and their number of scans a day/week. This encourages customers to evaluate what they charge for diagnostics. They realize that the diagnostic fee could be modified to easily cover the investment cost of an upgraded diagnostic tool.

TWO-A-DAY

Without fail, we demo a diagnostic platform and present a written quote to at least two customers every day.

Hayden presenting a quote last Thursday morning. He sold

that customer an APOLLO-D9. The store is just about sold

out of diagnostic tools. Time to restock the shelves!

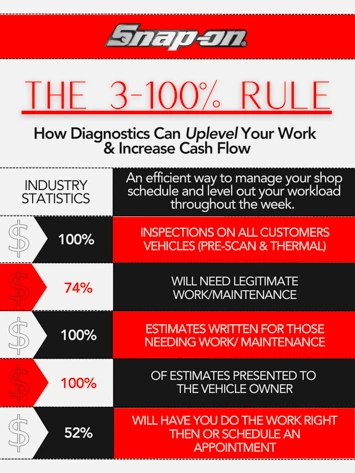

3-100% RULE

We share the 3-100% rule to shop owners when we see the opportunity. The rule is simple — just a three step formula.

#1 Inspect 100% of the vehicles that come thru the shop (pre-scan and thermal inspection)

• 74% of those vehicles will need work/maintenance

#2 Estimates written for those needing work/maintenance

#3 Present those estimates to 100% of those customers

• 52% will approve the work

Aleshire's — Congratulations on the outstanding work and future successes! Thank you for sharing your story with our Snap-on® community.