Unlocking the Full Potential of Your Snap-on® Diagnostic Platform ®

ADAS is now standard on most vehicles, with features like adaptive cruise control, lane keeping, and emergency braking designed to improve safety. As a technician working with a Snap-on® diagnostic platform, you have the tools to manage ADAS service and recalibration with precision. This article explores how your platform supports each stage—from fault detection to recalibration and reporting—so you can make the most of its capabilities.

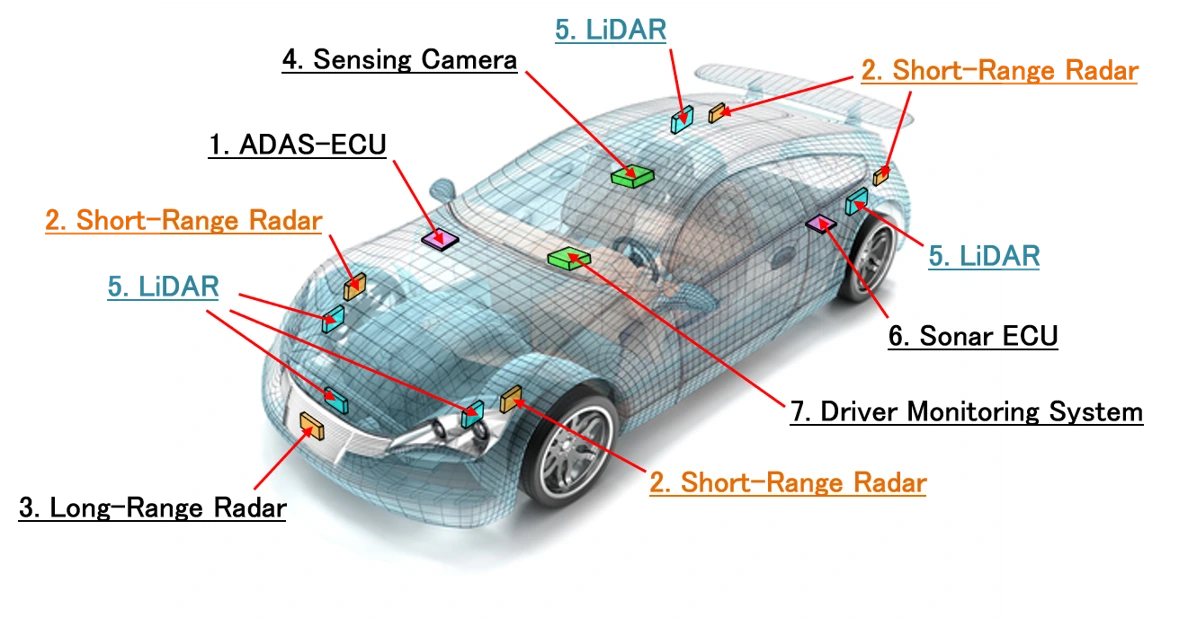

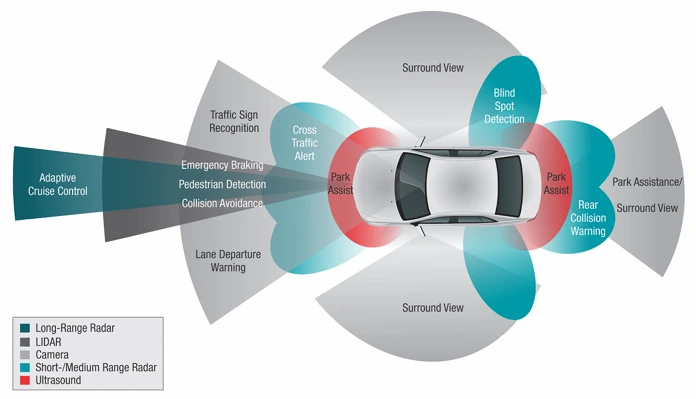

ADAS Sensor Overview

ADAS sensors include front and rear cameras, forward RADAR, ultrasonic parking sensors, and blind spot detection RADAR. These work together to monitor surroundings, aid manoeuvres, and enhance driver safety.

Understanding sensor configurations ensures precise recalibrations and thorough diagnostics, maintaining system reliability and driver safety.

Routine Repairs, Critical Recalibrations

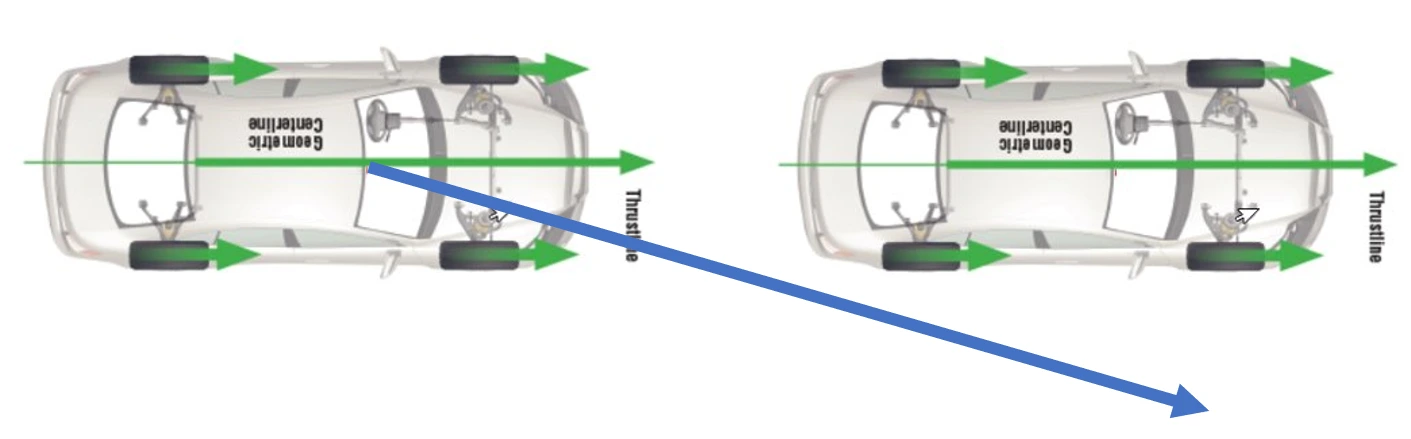

ADAS components—cameras, RADAR, and ultrasonic sensors—must be precisely aligned. Minor repairs like bumper removal or suspension work can disrupt positioning. Recalibration restores accuracy. Without it, sensors can misjudge distances or lane positions, creating potential risks.

With ADAS now standard, recalibration is a routine task. Your diagnostic tool supports safe, compliant repairs—and helps grow your service offering.

ADAS Recalibration Methods Explained

Your Snap-on® platform supports all three main recalibration types with built-in guidance:

- Static Recalibration: Uses physical targets (optional accessories) in the workshop at set distances and angles. The tool monitors and verifies system responses.

- Dynamic Recalibration: Performed while driving under specific conditions with real-time prompts and confirmation.

- Initialisation: Required after new component installation to align modules and sensors and set system parameters.

Why is ADAS Recalibration Necessary?

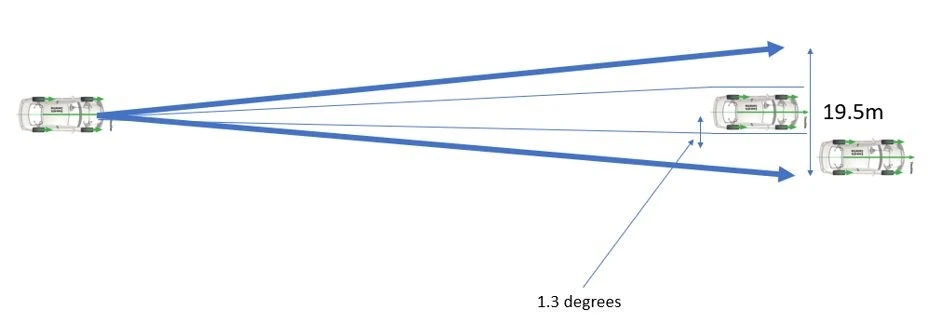

Consider a front-facing camera with a 7-degree field of view, covering about 19.5 metres at 160 metres distance. A motorway lane is around 3.65 metres wide; a small misalignment of roughly 2.2 millimetres can significantly affect the camera’s ability to correctly interpret lane markings or obstacles.

Even minor misalignments can cause hazards. Recalibration ensures systems function correctly. Each manufacturer has unique recalibration steps. Your Snap-on® tool simplifies this by delivering OEM-specific guidance tailored to the vehicle—reducing errors and saving time.