Modern body electrical systems no longer resemble the simple switched circuits technicians grew up diagnosing. Windows, mirrors, wipers and lighting functions are now controlled by multiple modules communicating across vehicle networks. Understanding how these systems operate, and how to approach them diagnostically, is essential for reducing diagnostic time and avoiding unnecessary component replacement.

This technical focus looks at body control functions through real-world examples, highlighting how a scan-tool-led approach transforms fault-finding on modern vehicles.

Body Electrical Systems: past vs present and beyond

Traditional Body Electrical Diagnosis

On older vehicles, body electrical circuits were relatively straightforward. Take a 2001 Chevrolet Tahoe rear window motor as an example.

Typical circuit elements included:

With so few components involved, fault-finding focused on checking continuity, voltage supply and switch operation. Although trim removal could be time-consuming, the diagnostic logic was simple and linear.

How Modern Body Control Systems Operate

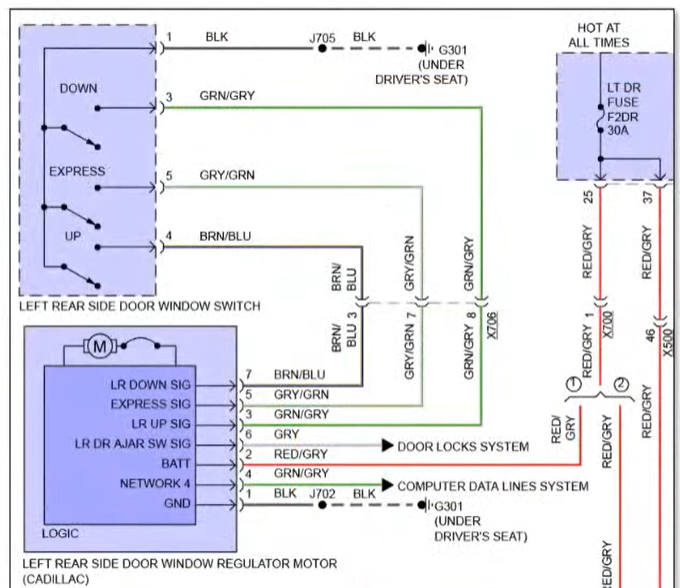

Fast forward to newer vehicles and the same function becomes significantly more complex, on a 2016 Chevrolet Tahoe, the left rear window switch is no longer just a switch, it is a module.

In addition to power and ground, the switch is connected to:

Integrated Motor and Logic Modules

Some vehicles go a step further. On the 2016 Cadillac Escalade, the motor, switch logic and control electronics are integrated into a single assembly.

Commands are transmitted over the local interconnect network (LIN) bus, with the module interpreting data messages that determine window operation.

On this platform there are four separate LIN buses. The rear window switch operates on LIN Bus 4, a 12-volt single-wire network. When viewed on a scope, this produces a square-wave signal with a constantly changing data pattern.

The physical switch inputs are processed locally, and the module then sends data signals, such as door ajar status, across the network. While the exterior function appears familiar, the internal operation is entirely different.

This is why applying older diagnostic habits to modern body systems often leads to wasted time and incorrect conclusions.

Body Control Module Overview

Common inputs include:

Common outputs include:

The module processes inputs, makes logic-based decisions and commands outputs — often across networks rather than direct wiring.

Case Study: 2011 Jeep Liberty Rear Wiper

Customer complaint: Rear wiper inoperative

At first glance, this could involve:

Traditional diagnosis might involve removing trim panels and chasing wiring — a time-consuming process with no guarantee of a quick answer.

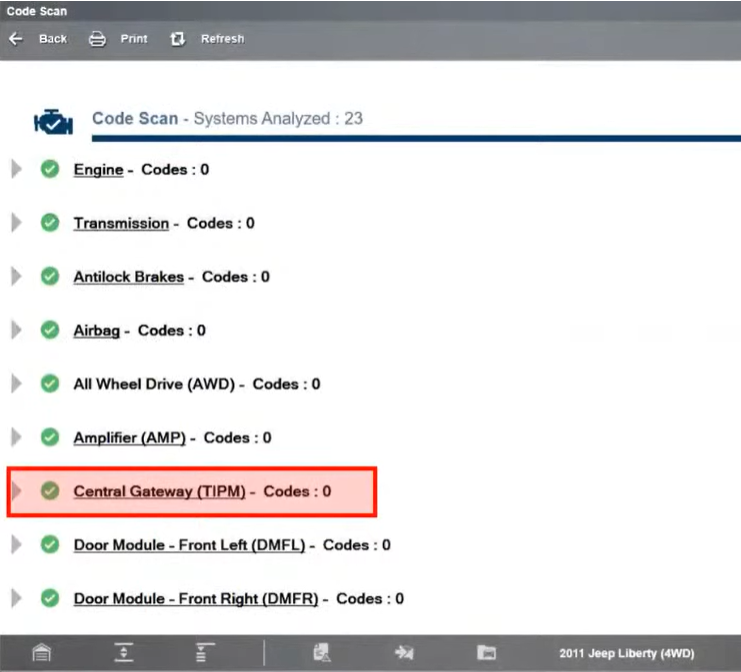

Step 1: Pre-Scan the Vehicle

Begin with a full vehicle pre-scan. In this case, no diagnostic trouble codes were present.

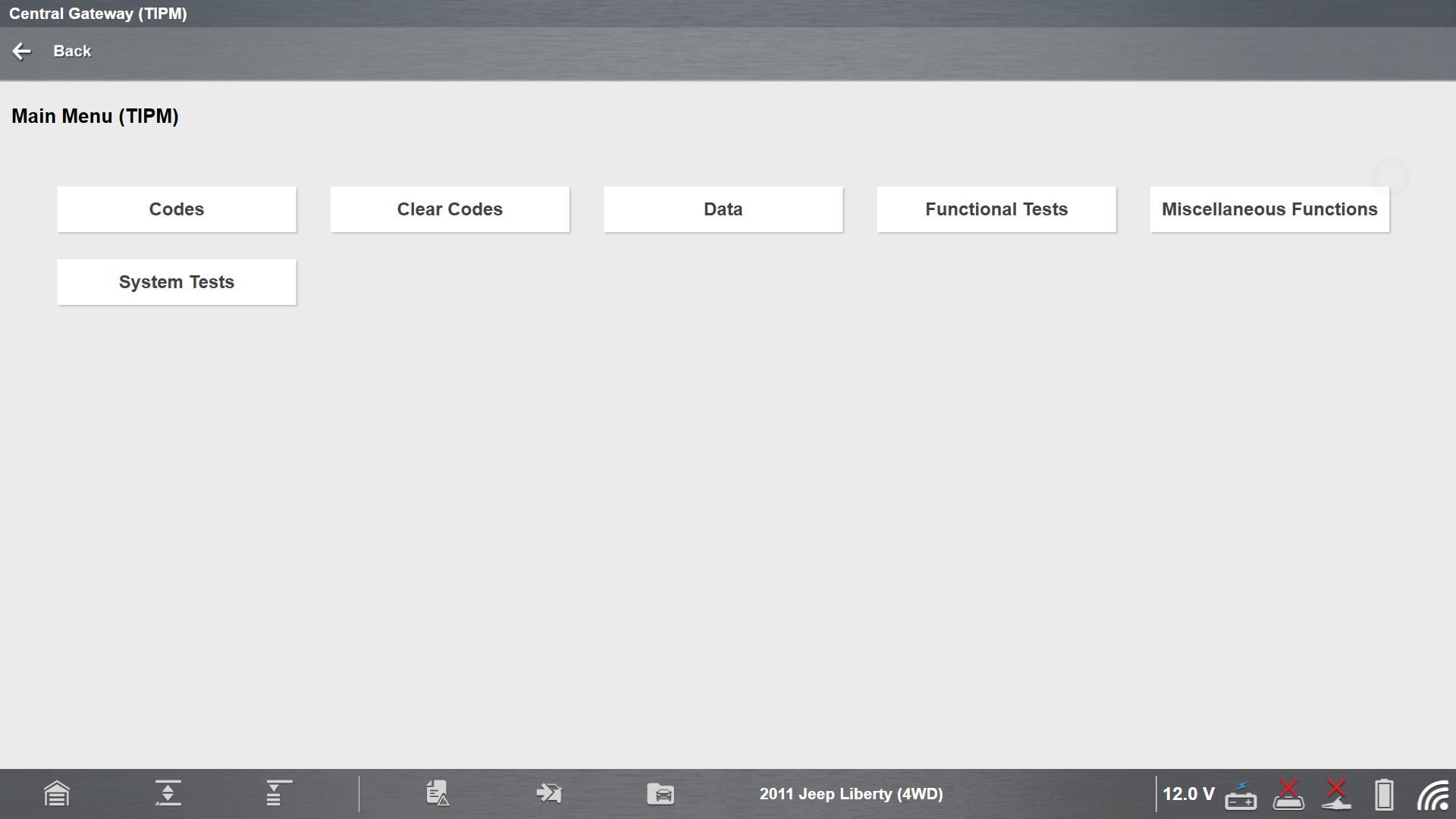

Next, access the Central Gateway / totally integrated power module (TIPM).

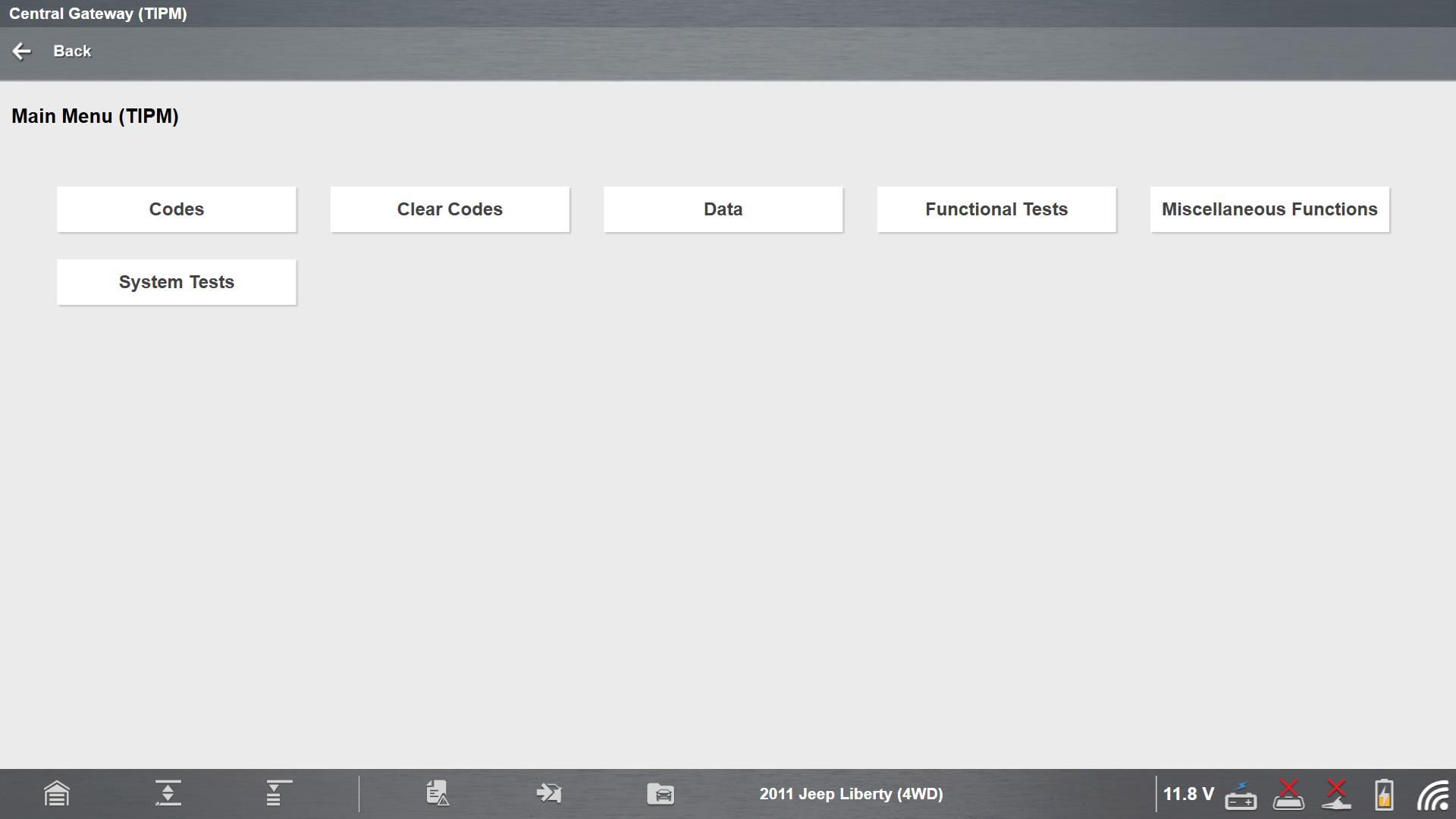

Step 2: Use Functional Tests

Navigate to:

Functional Tests → Rear Wiper

From here, the rear wiper can be commanded ON or OFF directly from the scan tool.

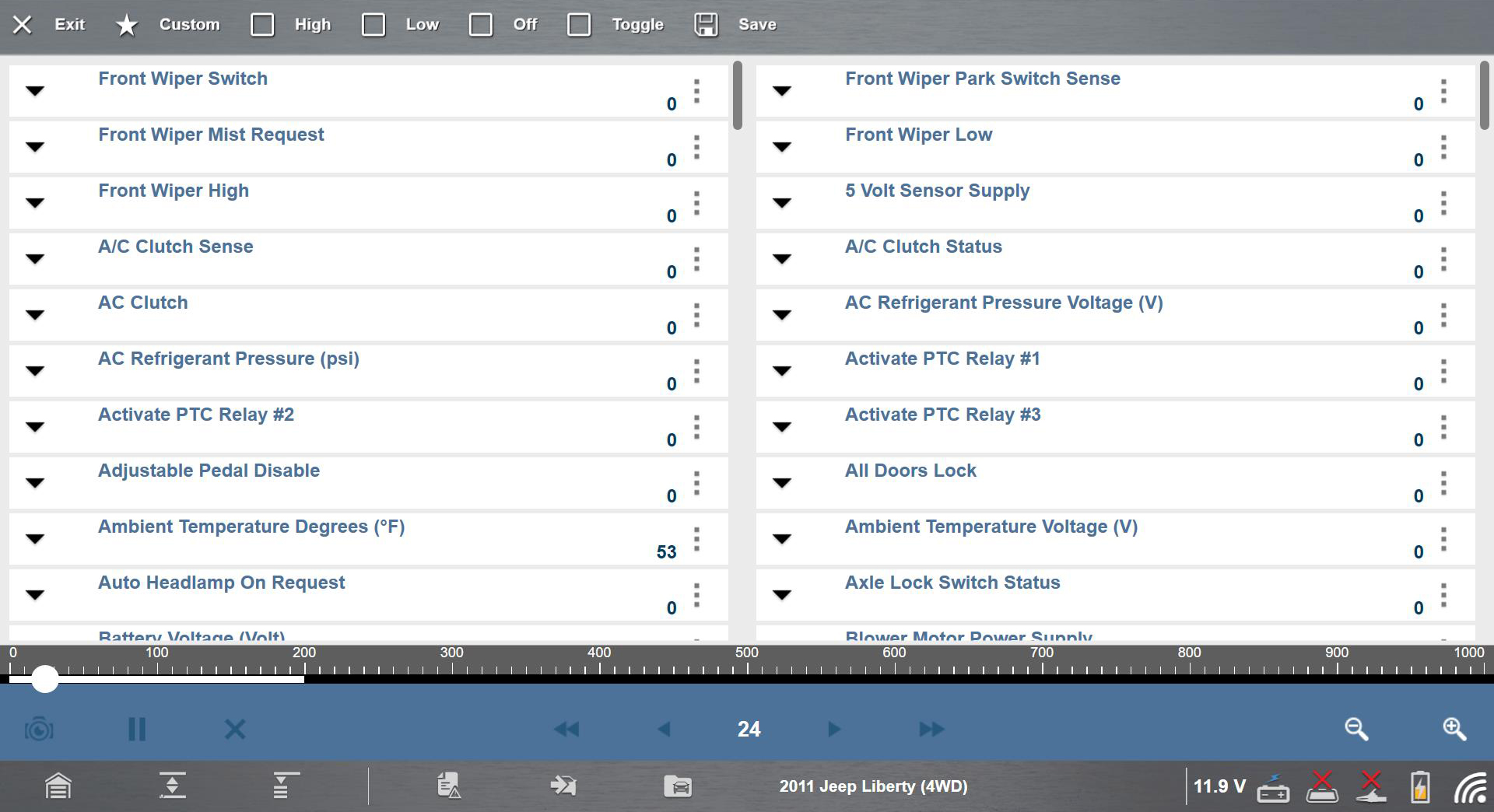

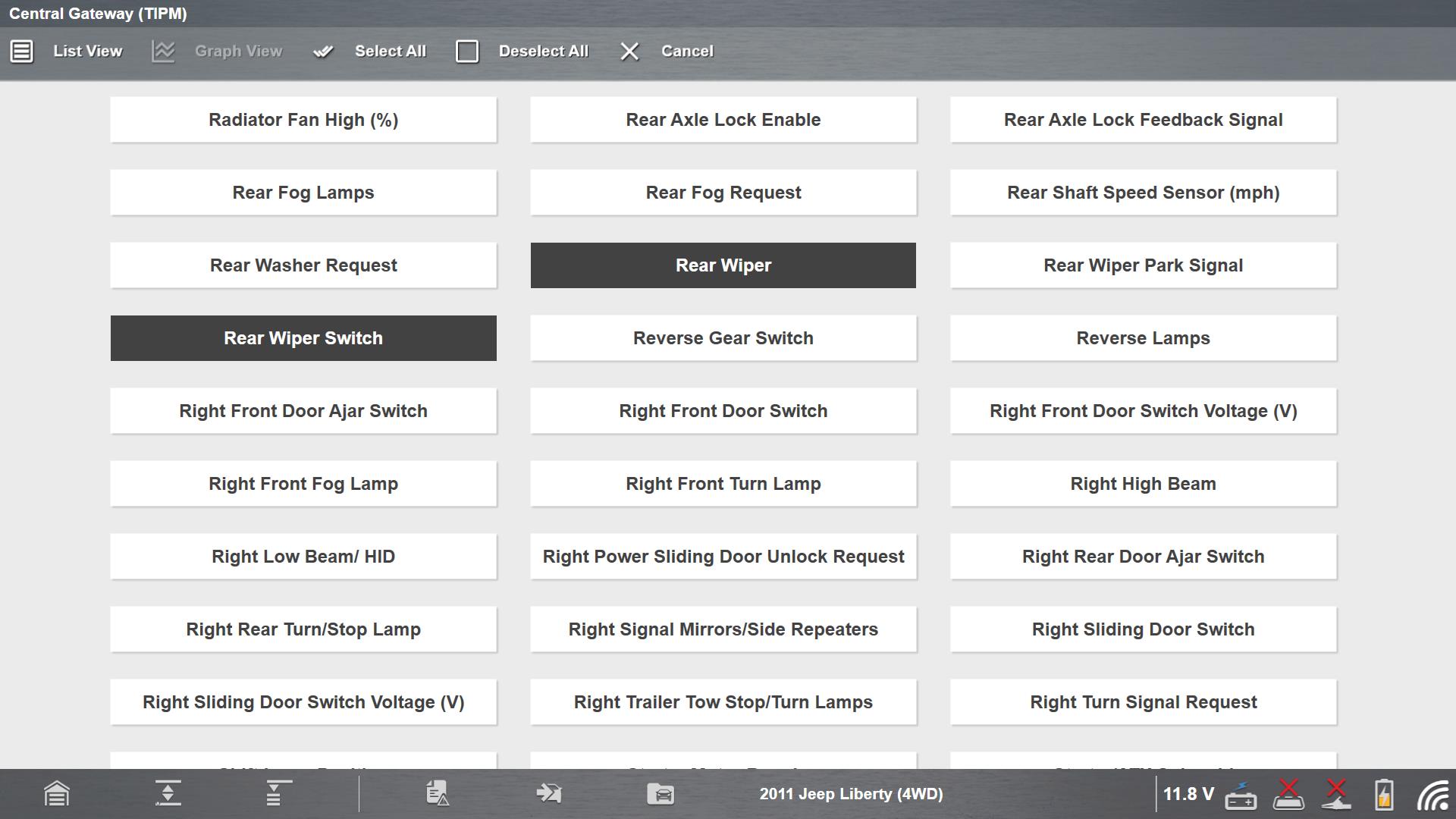

To simplify analysis, use the Custom Data List feature:

Deselect all parameters

Select only Rear Wiper and Rear Wiper Switch

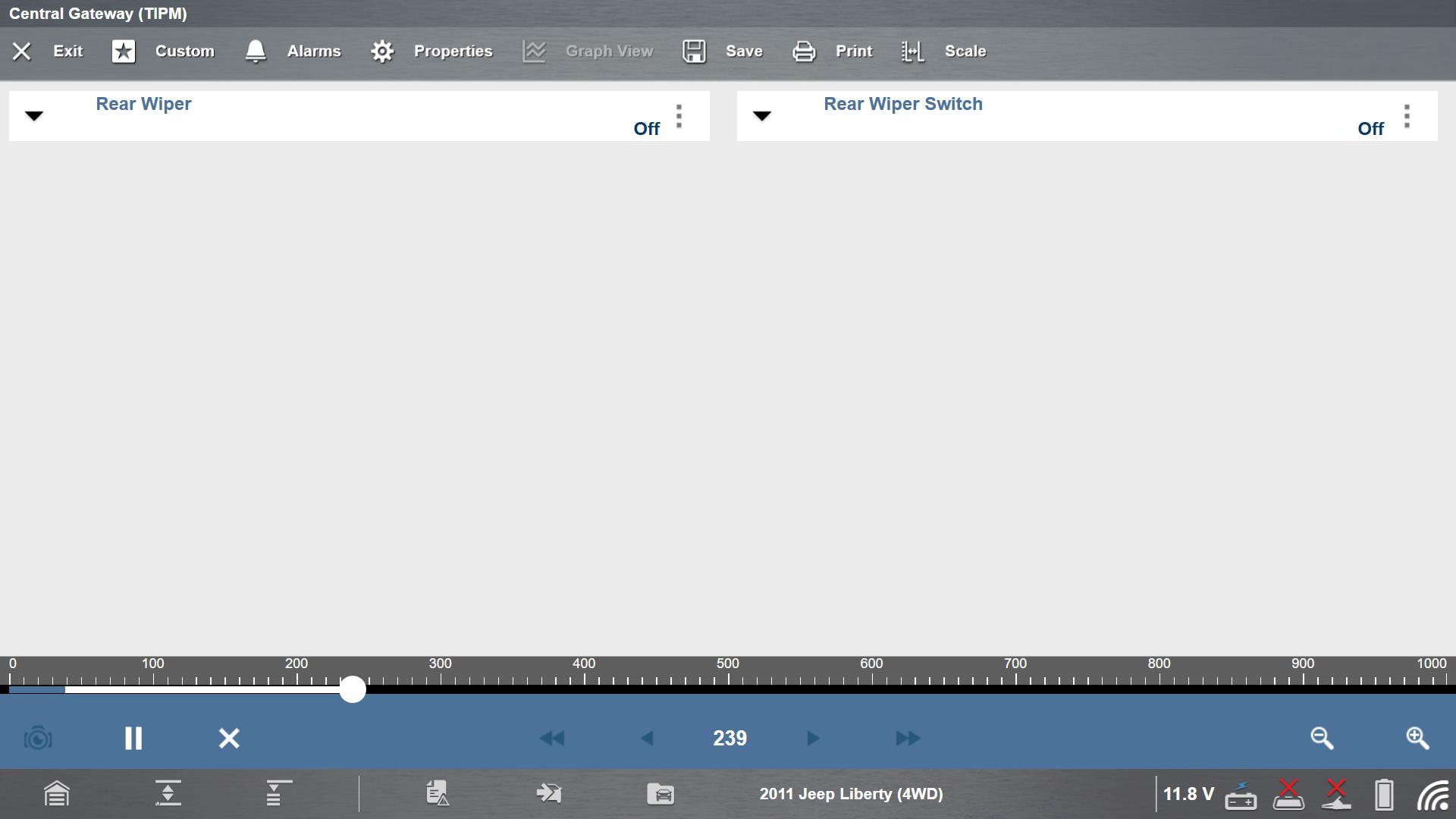

Verify the Output Side

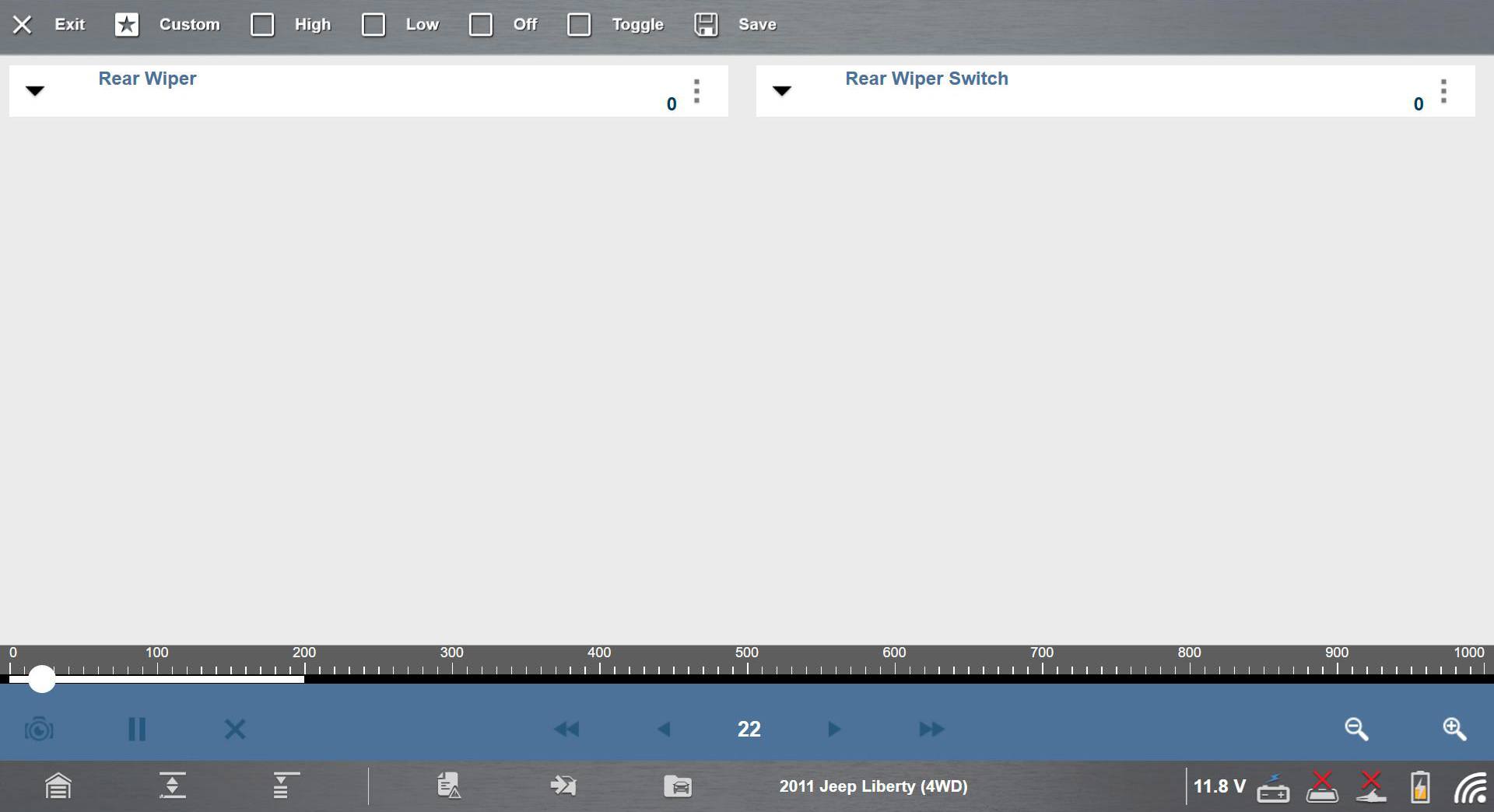

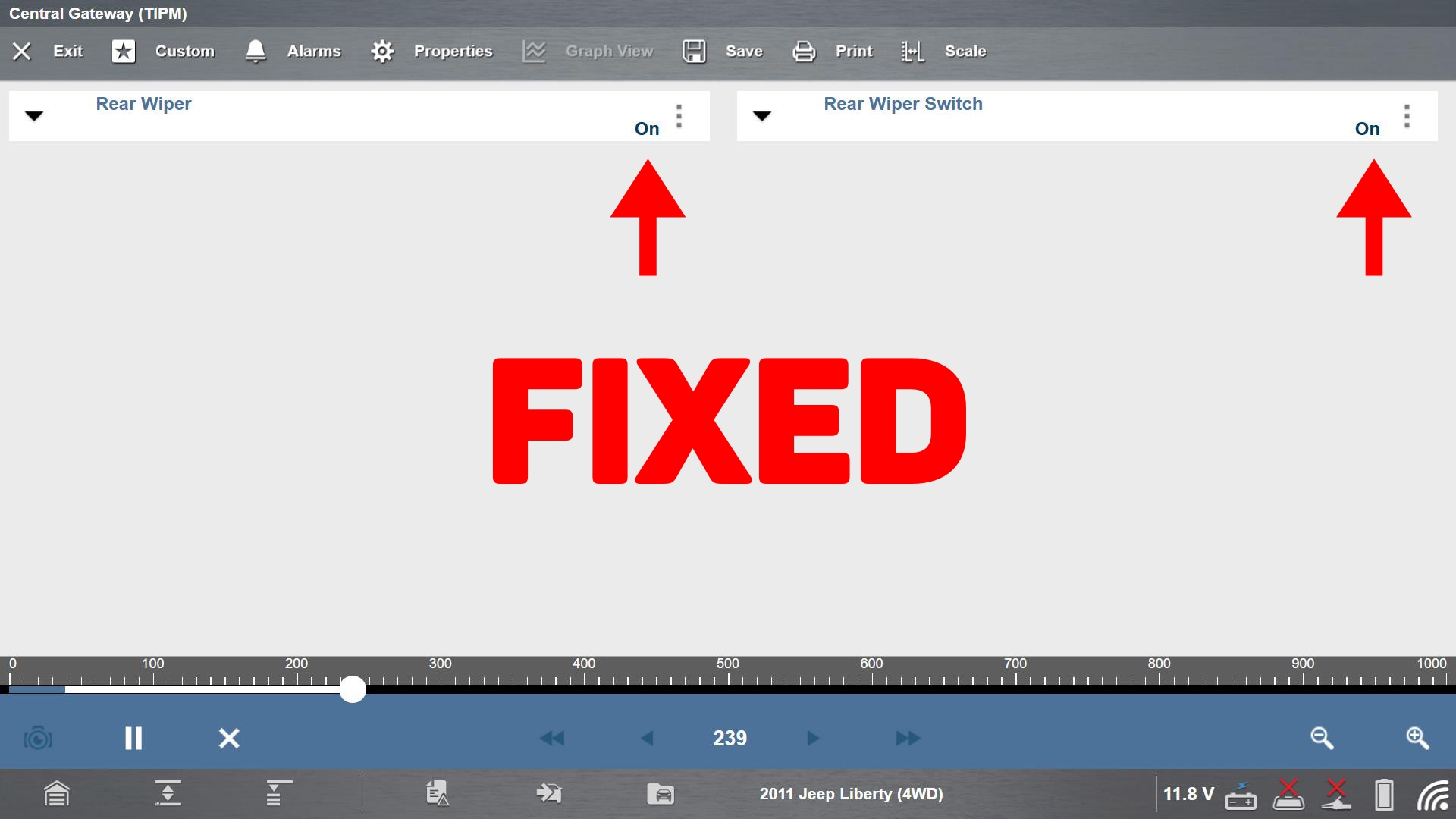

Return to list view. Below you’ll see just the rear wiper and rear wiper switch. Simply toggle the on /off functions and you’ll see the ON/OFF status of both the rear wiper and the rear wiper switch. Then confirm visually that the rear wiper is wiping.

Using the functional test to turn on the rear wiper we have verified that half of the circuit is working. This is good news, as now we know that everything between the TIPM to the motor is working when it is commanded on from the scan tool, therefore there is no need to check the motor, chase the wires on the harness, or verify the output of the TIPM is functioning, in around a minute we’ve verified that one half of the system is operating as intended and already saved a ton of time.

Step 4: Verify the Input Side

We can now check the data stream to verify the input side of the circuit.

From here, if we turn the rear wiper switch within the vehicle, and nothing happens, as in this case the tool display is off for both the rear wiper and the rear wiper switch, then we know that the module does not see the wiper switch.

Possible issues could be: the switch, the wiring or the BCM, but now we know where to look. Checking the data helps to verify the input side. In this case, the TIPM is not receiving a signal from the switch. Upon further investigation the switch was found to be bad and the switch was replaced.

Step 5: Confirm the Repair

After replacing the switch:

Operate the switch again

Observe correct ON/OFF status in data

Confirm rear wiper operation visually

This confirms correct system operation without unnecessary component testing. Verifying inputs and outputs using your scan tool will save a ton of time removing panels, chasing wires etc

Module Replacement: Coding and Relearn Procedures

The Jeep Liberty case study highlights how verifying inputs and outputs can quickly isolate faults. However, it also reinforces a wider point: many body control modules will not function correctly after replacement until coding or relearn procedures are completed. Modern vehicles store configuration data within body modules to match the vehicle’s equipment level, network layout and comfort features. When a module is replaced, this information is often missing or incorrect, leading to partial or complete loss of functionality.

Common Body Modules That May Require Coding or Relearn

Depending on the vehicle, this can include:

Without completing the correct post-installation procedure, symptoms can range from inoperative features to network communication faults.

Body shop Diagnostics: Mercedes-Benz Metris / Vito (2016–2023)

A common body shop scenario involves replacement of the door mirror module on Mercedes-Benz Metris or Vito models. Module replacement often requires coding or relearn procedures before full functionality is restored.

After fitting a new mirror module, the vehicle may exhibit:

This is because the new module must be coded or relearned to the vehicle, so it understands its role on the network and the options it is expected to support.

Using the appropriate diagnostic procedure, the coding or adaptation procedure restores full functionality and ensures the module communicates correctly with other body systems.

For body shops, this step is critical. Mechanical replacement alone is no longer enough — electronic configuration is now part of the repair.

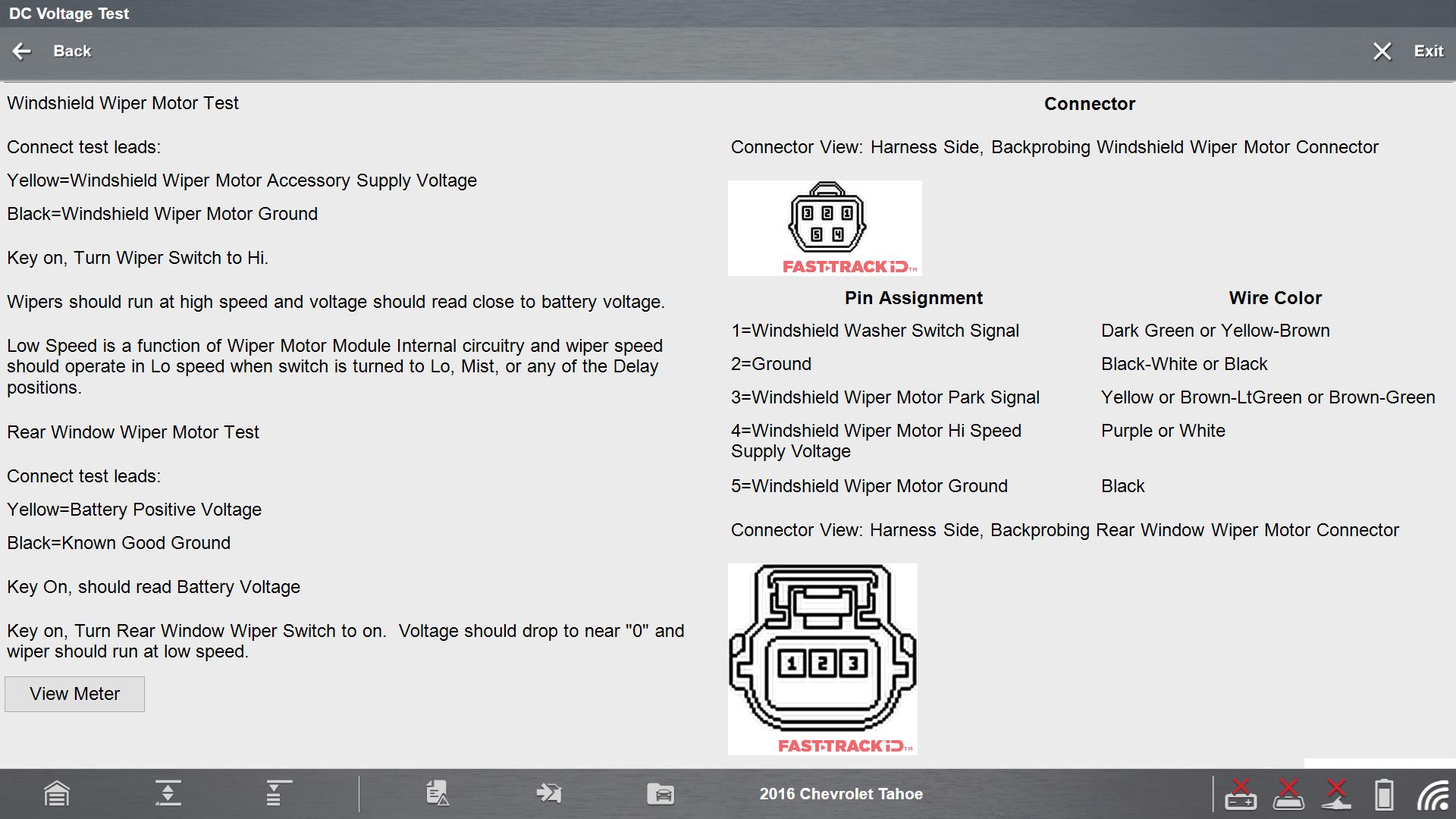

Fast-Track® Guided Component Tests

Many vehicles include a dedicated Body Electrical category within Snap-on® Diagnostic Software, giving technicians direct access to system-specific test information without leaving the diagnostic workflow.

These Guided Component Tests provide valuable insight, including:

By integrating this information directly into the software, technicians can diagnose body electrical faults with greater confidence. There’s no need to search online, cross-reference multiple manuals or rely on assumption, helping support accurate diagnosis, first-time fixes and reduced risk of vehicle returns.

Faster Body Electrical Diagnostics with Snap-on Guided Component Tests

Body electrical faults no longer need to involve hours of trim removal and wiring checks. By understanding how modern body control systems operate, and using scan tool data and functional tests effectively, technicians can isolate faults quickly and confidently.

Explore the body electrical functions and guided component tests within your Snap-on® car diagnostic tool to streamline diagnostics and reduce vehicle downtime.