Learn how to get the most from Snap-on® Diagnostic Software when working on diesel vehicles. This article walks you through DPF regeneration, AdBlue dosing, and NOx sensor checks, while showing how to monitor the full diesel emission system workflow. For more detailed troubleshooting tips, a linked Technical Focus article provides extra guidance.

Simplifying DPF, AdBlue, and Sensor Testing

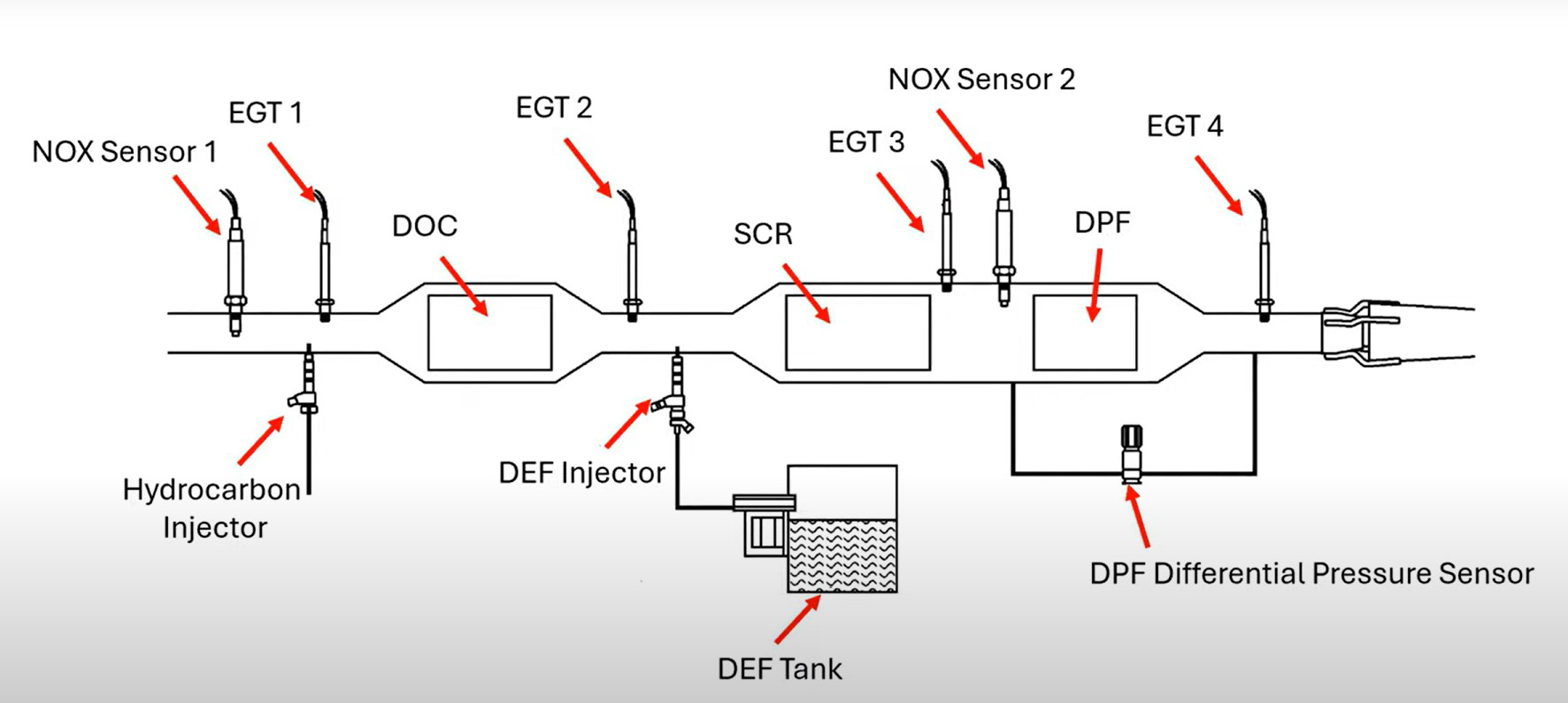

Modern diesel vehicles feature complex emission control systems, from NOx sensors to SCR (Selective Catalytic Reduction) modules and DPFs (Diesel Particulate Filters). Professional diagnostics are critical for efficiency, compliance, and cost-effective repairs.

Snap-on® Diagnostic Software, when kept up to date on the latest release, provides technicians with guided workflows and repair procedures, allowing them to:

If you're not on the latest software release, technicians risk missing key updates, diagnostic functions, and guided procedures, which could slow down troubleshooting or lead to incomplete verification of repairs.

For an in-depth look at diesel emission system verification, including NOx and SCR monitoring, see our Technical Focus Article, Understanding and Diagnosing Diesel Particulate Filter (DPF) Systems: Diesel System Diagnostics: NOx, SCR, and DEF Verification

Understanding NOx and Ammonia Sensors

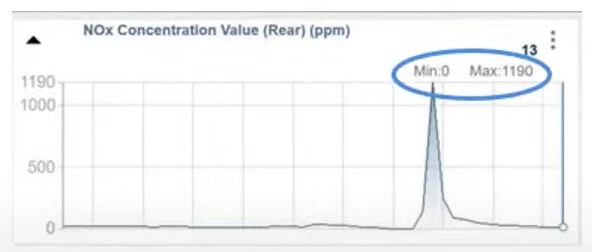

NOx sensors are central to emission control, measuring nitrogen oxide levels at both the inlet and outlet of the SCR system. While highly effective, conventional NOx sensors can misidentify ammonia as NOx, leading to falsely elevated readings. Some manufacturers incorporate additional ammonia sensors to improve accuracy and prevent interference from other exhaust gases.

Key Points:

Example Check:

Partial failure: Intermediate readings indicate malfunction in the NOx sensor or SCR system.

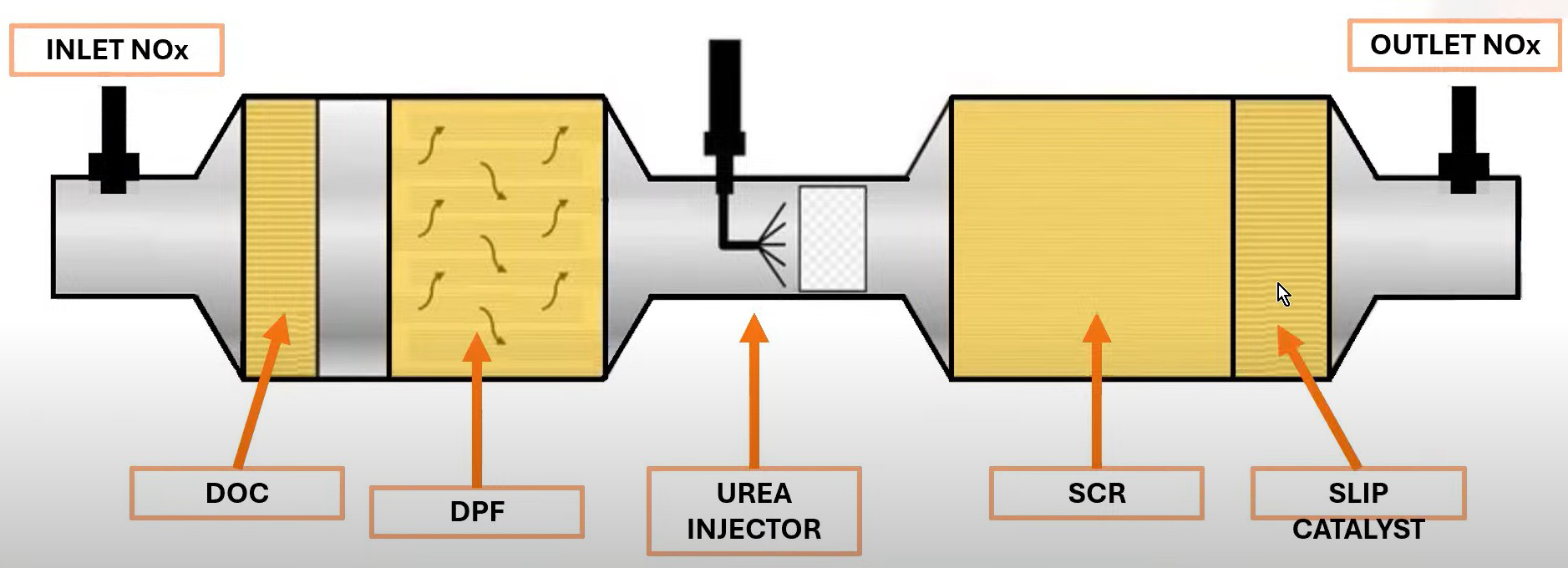

Diesel Emission System Workflow

DPF → Urea Injector → SCR → Slip Catalyst

Typical diesel emission systems follow this sequence:

Snap-on® Diagnostic Software allows technicians to monitor and test each stage:

Safety Note: Manual DPF regeneration generates extremely high exhaust temperatures (>1000°F / 538°C). Always perform outside, away from personnel and combustible materials.

Regen Types:

Diesel Functional Testing with Snap-on® Software

The latest Snap-on® Diagnostic Software release gives technicians exclusive access to guided workflows that streamline diesel functional tests, helping to identify the root cause quickly and verify repairs with confidence.

DPF Regeneration

AdBlue® / SCR Testing

SCR systems require precise dosing of AdBlue® to convert NOx into harmless nitrogen and water. Functional tests include:

Sensor Integrity

Reliable sensors are critical for emissions control. Snap-on® software enables technicians to:

Guided Component Tests

Snap-on® exclusive guided component tests provide step-by-step instructions for sensors, pumps, heaters, and valves, allowing technicians to verify repairs and prevent costly comebacks.

Example NOx Workflow:

Vehicle Specific Workflows

While general coverage is essential, what matters most is how these tests apply to the vehicles you see in the workshop. Snap-on® diagnostic platforms provide a deeper functionality for a wide range of diesel vehicles, including advanced system support and embedded safety guidance.

Mercedes Sprinter

Ford F350

Jeep Renegade