Since 1995/96 in North America and 2001 in the UK and Europe, trouble codes have been standardised.

P codes stand for a problem in the powertrain. B codes stand for body and C stands for chassis codes. Can you see the trend?

If there is a problem in the Controller Area Network (CAN bus), a code where different modules stop communicating, then a U code is set. Wait, P = powertrain, B = body, C = chassis… shouldn’t a network problem be an N code? Well, it’s not. The only thing I can see is it's based on how difficult and expensive these network problems can be. When most techs see a U code pop up, they say uh oh!

What Are Diagnostic Trouble Codes? Breaking Down P,B,C, and U Codes

Explaining CAN Bus: The Backbone of Modern Vehicle Communication

CAN Bus Made Simple: How Vehicle Modules Talk to Each Other

What Do U Codes Really Mean? Diagnosing Network Interruptions

What Is CAN FD? A Faster, Smarter Network for Today's Vehicles

How Scan Tools Interact with the CAN Network and OBD-II Connector

The Problem with U Codes: Why Most Scanners Fall Short

Snap-on® Diagnostics: Real Fixes with Fast Track® and SureTrack®

Explaining CAN Bus: The Backbone of Modern Vehicle Communication

Let’s back up and discuss CAN bus. A CAN bus is a communication system used in today’s vehicles that enable electronic control units (ECU) to communicate with each other without needing a central computer.

How CAN Bus Enables Module Communication

It's a message-based protocol, meaning devices on the network can send and receive messages. It’s the communication network for control modules; Controller Area Network, making sense now, but what about bus?

CAN Bus Made Simple: How Vehicle Modules Talk to Each Other

In electronics, a bus is a highway that allows multiple components to communicate by transmitting data. In the case of CAN, the highway connects controllers together. When explaining CAN bus to non-technical folks, I say they should think of bus, as a bus. Yes, a bus with wheels and seats. In the seats will be data instead of people, at each bus stop (a control module) the bus driver says, “Any data wanting to get off? Any data wanting to get on?” The bus driver is the network itself, driven by the interaction of various components, primarily microcontrollers, CAN controllers and transceivers that work together to facilitate communication.

What Do U Codes Really Mean? Diagnosing Network Interruptions

Now think about a U code as the bus has a flat tire and communication stopped at the bus stop where you got the flat tire. The U code identifies the bus stop, but not which tire went flat. More on that later.

What Is CAN FD? A Faster, Smarter Network for Today's Vehicles

How CAN FD Improves Data Transfer Rates

I'd better mention CAN FD before we hop back on the bus. FD stands for Flexible Data-Rate. Basically, it is a faster and bigger bus. The FD bus is five to eight times faster than the classic CAN bus. So, the FD bus has a nitrous valve, metaphorically. There are eight times more seats on the bus, so eight times the data can be picked up and delivered.

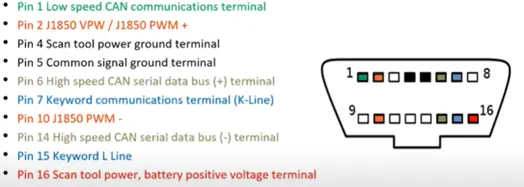

When a scan tool is connected to a vehicle's OBD-II connector, it becomes a “bus stop,” a module on the bus route. This allows the scan tool to monitor and interact with the data circulating on the network, enabling diagnostics and troubleshooting. Note that the CAN pins on the connector are where the data gets on and off the bus. If you ever plug your scan tool in and receive a no communication error, do you blame the scan tool or the car? The CAN pins, seen below, need to be checked using Snap-on® guided component tests to determine communication quality.

The Problem with U Codes: Why Most Scanners Fall Short

Most scanners show U codes and offer a basic description. Some will even map out the network (topology) to give a general direction, saying, “The problem might be over there somewhere.” But that’s where it stops... no troubleshooting steps, no further guidance. You’re left guessing and that gets expensive.

Snap-on® Diagnostics: Real Fixes with Fast Track® and SureTrack®

Snap-on scanners run full-system scans, pinging each module and reporting all codes, but what makes the difference is the Fast Track® Intelligent Diagnostics workflow and SureTrack®. These are real-world tips, common fixes and guided steps taken from billions of actual repair data submitted by techs across North America. Instead of just finding the effect of the issue, you’ll know the cause and how to fix it.

Going Beyond the Code: Pinpointing the Cause, Not Just the Symptom

Snap-on doesn’t just read codes; it delivers what other tools don’t. Snap-on provides real-world fixes. In other words, this “real world” information takes you across the “fixed-it finish line.” This information not only gives you the bus stop location where the bus had a flat tire, but which tire went down and what caused it to go flat.

Case Study: How Snap-on Diagnosed a U0403 Code with Real-World Data

A perfect example of this is a troubleshooter tip on a vehicle with a U0403 code, invalid data received from the transfer case. Topology would point to the transfer case module. In other words, the problem is over there somewhere.

On a Snap-on tool, the tip states that a population of these vehicles left the factory with the ABS ground strap not fully tightened. The ABS module ground, not the transfer case module. The problem is at a completely different bus stop.

Avoid Costly Misdiagnoses with Guided, Data-Driven Troubleshooting

I wonder if a technician who did not have access to this tip would end up replacing the transfer case module only to find the problem still exists. I think all of us know that feeling. Sooner or later, this vehicle will make its way to a technician who has access to this real-world tip. Then it will cross over the fix-it finish line.

That’s the power of staying connected to the right knowledge. If you found this helpful, there’s plenty more where it came from. Check out more technical insights and diagnostic case studies from Snap-on® Diagnostics.