This article is designed to provide a technician with a process for identifying a parasitic draw from a vehicle battery.

The key to diagnosing any parasitic draw issues is ensuring that the vehicle is shut down. After the ignition is switched off, many modules can still be powered up and communicated on the vehicle's network for a substantial period. Normally a vehicle will shutdown fully within 10 minutes. However, some vehicles may “wake up” again after a few minutes. This will make it more difficult to identify a parasitic draw as opposed to normal vehicle behavior.

Another point to remember is that vehicles with Keyless Entry need to remove the ignition key from the area around the vehicle, as this may force the vehicle to stay awake.

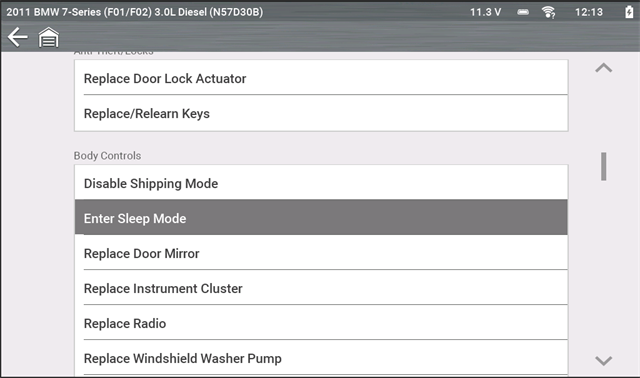

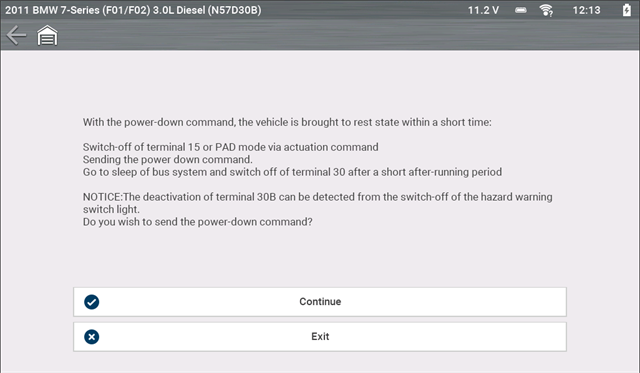

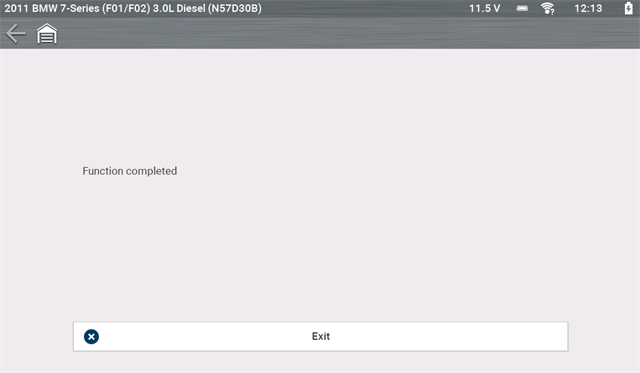

BMW vehicles have a Functional Test called “Enter Sleep Mode”, it can be found through the Service Resets and Relearns menu under the category 'Body Controls'. This function forces the vehicle's network to shutdown to enable the technician to test the vehicle for a parasitic draw without having to wait for the vehicle systems to fully shutdown.

Any value found above specifications indicates a parasitic draw. A good guide is less than 50 milliamps current draw.

Service Resets and Relearns:

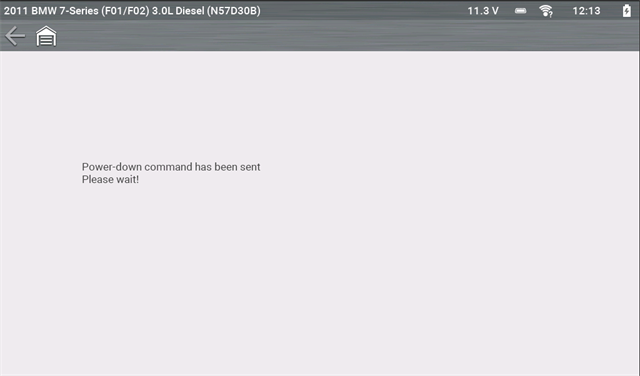

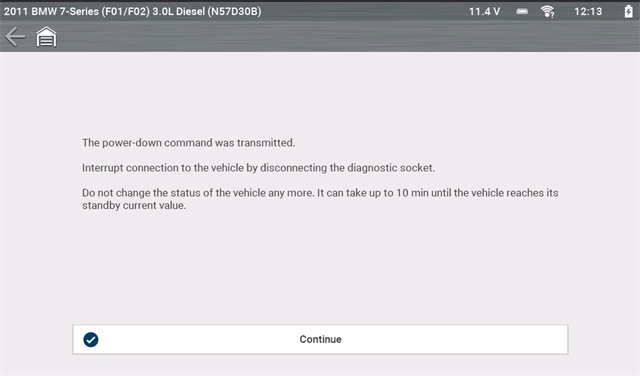

The screenshots below show the procedure for shutting down the vehicle.

Don’t forget to disconnect the scantool from the Data Link Connector. Pin 16 of the DLC is constantly live so the scantool will stay powered up.

(J1962 Data Link Connector)

Current Measurement:

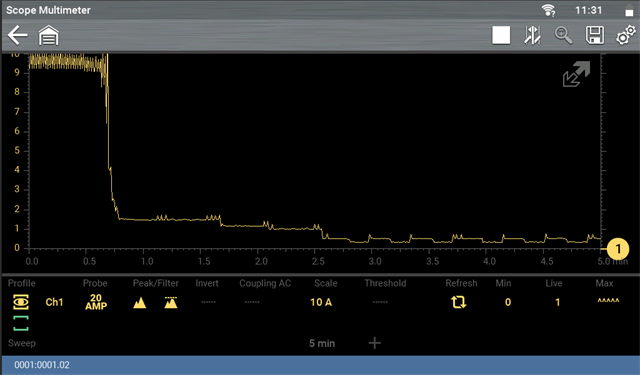

The waveform below shows the current measurement during a normal shutdown, measuring at the negative lead of the vehicle battery. It can be seen after one and a half minutes, the current flow drops to approximately 500 milliamps. However, it cycles between high and low every 10 seconds until the vehicle network shuts down. This may cause confusion for the technician.

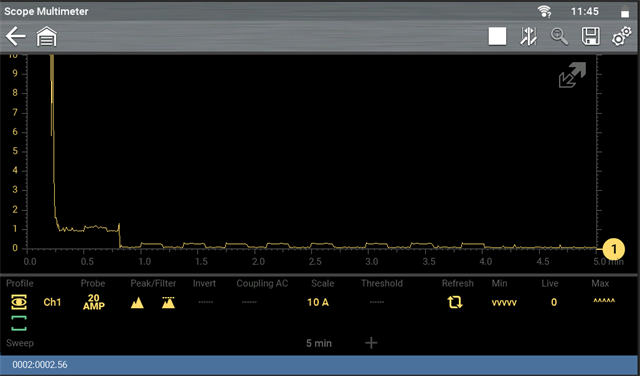

Using the function test, the network shutdown begins after approximately one minute. The vehicle is fully powered down after three minutes and forty-five seconds. The vehicle network will not be reinstated until the ignition is switched on or the central locking is activated.

Diagnostic Thermal Imager:

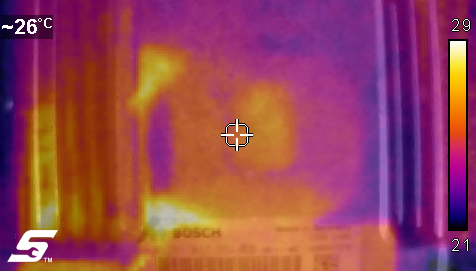

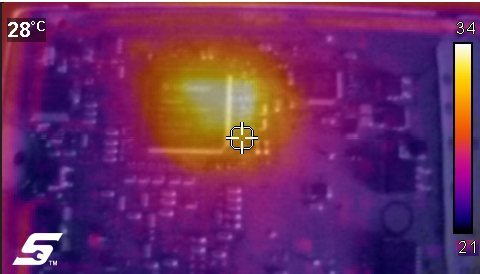

Below is an example of a vehicle with a parasitic draw and how the Snap-on Diagnostic Thermal Imager (DTI) can be used to identify a fault that is otherwise difficult to trace.

After ensuring the vehicle network is shut down and all current consumers are switched off, the current draw from the vehicle battery should be less than 50 milliamps. Anything above this value requires the technician to trace the source of the increased current flow.

A module that remains powered up after the vehicle's shutdown will cause a parasitic draw, which can be as high as 150 milliamps. One of the effects of current flow is the generation of heat energy. The DTI can be used to identify differences or unexpected temperature values.

The image below shows the outer casing of an Engine Control Module, it can be seen that there is a temperature difference detected, which should not be present if the module is not powered up.

Further investigation can be carried out, the localized heating around the Microprocessor can be seen and the heat dissipating away throughout the board.

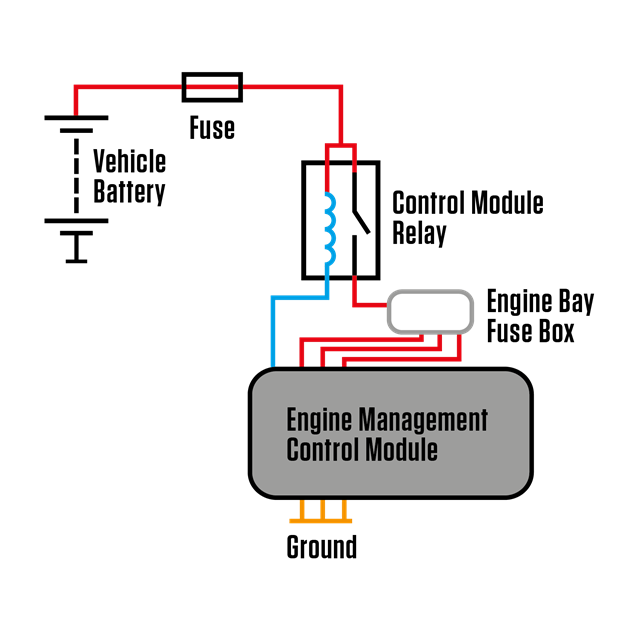

If a technician is faced with an issue like this, the vehicle wiring diagram should be consulted to test any other components associated with the circuit which may cause the control module to stay powered up.

The diagram below shows a typical circuit layout. An internal fault with the control module relay contacts would allow currents to flow to the control module as the module has a constant ground.

Parasitic draws can be very difficult for a technician to identify, so all available tools should be used to help improve the process and repair the vehicle quickly and efficiently.

This Diagnostic Quick Tip shows you how to relearn the system after a battery replacement using a scan tool.

TAKE A LOOK AT SNAP-ON THERMAL IMAGERS