Gasoline Particulate Filters (GPF), also known as Otto Particulate Filters (OPF) or Petrol Particulate Filters (PPF), are essential components in modern petrol engines. They capture fine particulates and soot before they can escape through the exhaust system.

While diesel engines rely on Diesel Particulate Filters (DPFs), GPF/OPF/PPF systems are specifically designed for petrol engines to meet EU6 and China 6 emissions standards. Regeneration is required to oxidise accumulated soot into ash, keeping the filter efficient and compliant.

Fast-Track® Troubleshooting Workflow provides filtered information to bring focus to the specific vehicle and code you’re working on, giving technicians a clear path to monitor, test, and perform GPF regeneration. Using exclusive software features including Guided Component Tests and functional tests, it ensures accurate diagnostics and repair certainty, helping to prevent costly comebacks.

When were GPFs introduced?

GPF/OPF systems first appeared around 2014, with Mercedes-Benz introducing them on the S500. Since then, adoption has expanded rapidly. By 2018, most petrol engines – and all Gasoline Direct Injection (GDI) engines – have been fitted with GPFs to comply with Euro 6 a, b, c, and d emissions standards. Today, they are standard equipment on nearly all modern petrol vehicles.

System Overview - How does a GPF system work?

Key components of the GPF system include:

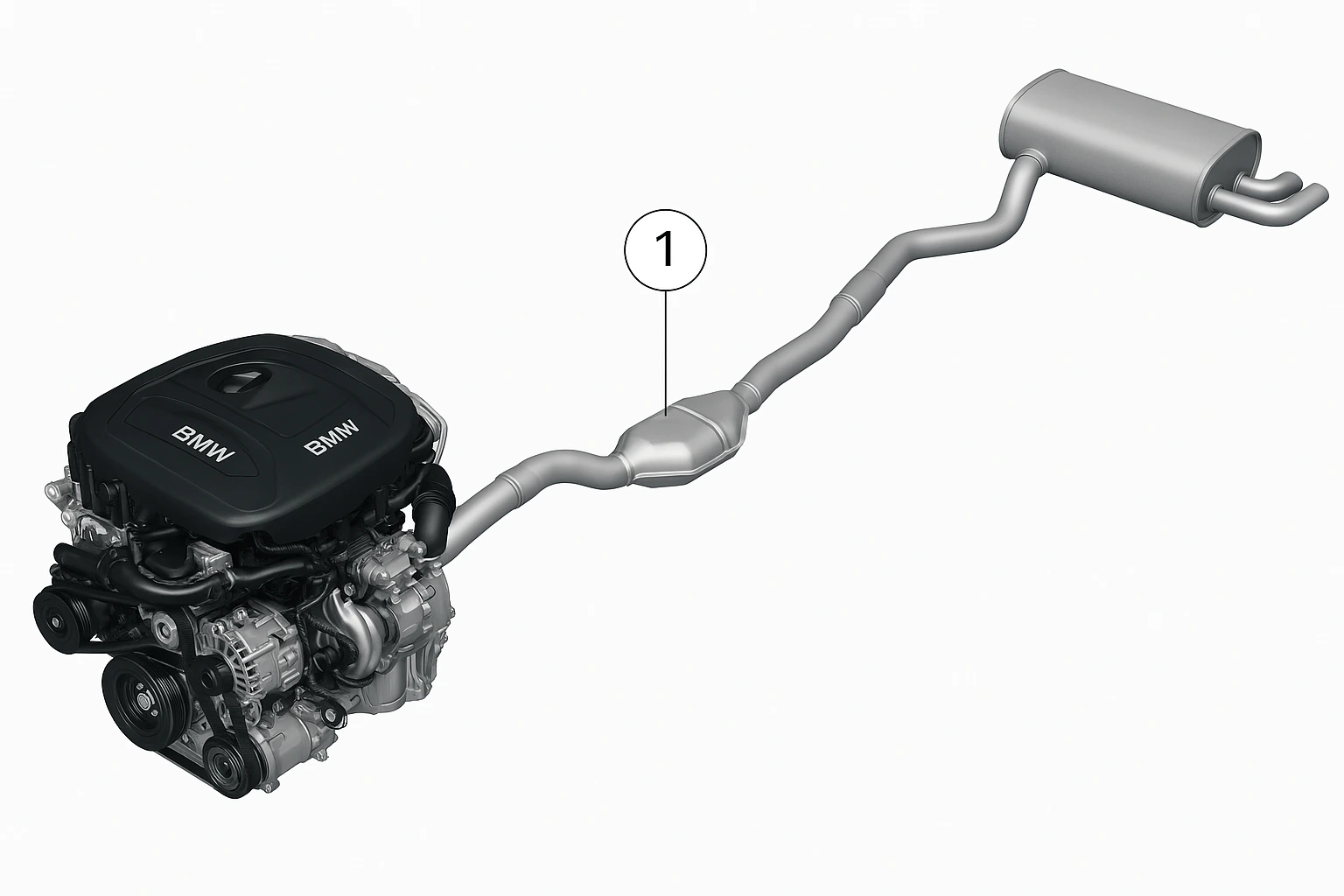

BMW B38A15 engine, exhaust system including Gasoline Particulate Filter (GPF)

Unlike diesel systems, gasoline engines produce lower soot loads, so regeneration occurs less frequently. Passive regeneration takes place during deceleration fuel cut-off events when oxygen enters the exhaust stream and temperatures exceed ~600°C.

Why do GPFs fail? Common GPF problems explained

Why Issues Occur

Despite robust design, several factors can affect GPF operation:

Typical symptoms: warning lights, limp mode, reduced performance, or a failure to complete regeneration independently.

Common Issues

With the latest Snap-on® Diagnostic Software and the Fast-Track® Troubleshooter workflow, you can diagnose the root cause based on the exact vehicle and code you are working on, then complete the repair with confidence.

How the System Operates

During normal operation, exhaust gases pass through the filter substrate, trapping particulates while allowing clean gases to exit the tailpipe.

Regeneration Process:

DTCs

Common GPF-related DTCs include:

No technician can remember every Diagnostic Trouble Code, Snap-on® products go beyond just identifying the DTC; they guide you through the diagnostic process, offering real-world insights that help you quickly get to the root cause of the problem. Check out our DTC list here.

Real world example - How to diagnose and regenerate a GPF:

Vehicle: 2020 BMW1 1-Series (F40) 1.5L Petrol Engine – B38A15

In the case of the BMW 1-Series, active regeneration may fail due to factors such as frequent short trips (where exhaust temperatures never reach regeneration levels), a defective exhaust pressure sensor, or incomplete regeneration leading to high backpressure. When this occurs, the vehicle may exhibit warning lights, reduced power, or limp mode, and diagnostic trouble codes (DTCs) such as P2452 – PPF Differential Pressure Circuit/Open can be logged, requiring further investigation.

Step 2: Petrol Particulate Filter Regeneration (GPF)

The regeneration when stationary is probably unnecessary. The engine is subjected to heavy strain during regeneration when stationary, therefore it is recommended to carry out regeneration when the vehicle has been driven for an extended period of time.

Petrol Particulate Filter Regeneration

This regeneration needs to be completed in the case of any of the following DTCs:

Complete the driving regeneration procedure (on-screen guidance provided).

Step 3: If Regeneration Fails

Petrol Particulate Filter: Initial Operation

Step 5: Final Checks

Key takeaways: Understanding and maintaining GPF systems

GPF (also known as OPF, and PPF) systems are now standard across modern petrol vehicles, playing a vital role in emissions control. Understanding their operation, recognising common faults, and using the right diagnostic workflow is critical for efficient repairs.

With the latest Snap-on® Diagnostic Software, Guided Component Tests, Troubleshooter Tips, and functional test coverage, you have the tools and information to manage GPF regeneration, diagnose accurately, and deliver confident, lasting repairs.

FAQs

What is a GPF?

A Gasoline Particulate Filter (GPF), also called OPF or PPF, traps fine soot and particulates from petrol engines to meet emissions standards.

When were GPFs introduced?

First fitted around 2014 (Mercedes S500); standard on most petrol engines from 2018 onwards.

How does a GPF work?

Exhaust passes through a ceramic substrate that traps soot. Regeneration heats the filter to ~600°C, oxidising soot into ash.

What triggers regeneration?

Pressure sensors detect soot buildup; the ECU increases exhaust temperature via air/fuel and ignition adjustments.

What are common issues?

Frequent short trips, faulty sensors, incomplete regeneration, high backpressure, or contamination.

What are the warning signs?

Warning lights, limp mode, reduced performance, or DTCs like P2452 and P2002.

How is it tested?

Use Guided Component Tests, DC voltage/signature tests on sensors, or a Mityvac to measure pressure across the GPF.

What if regeneration fails?

Inspect the filter with a borescope for damage; replace and program using Snap-on® Functional Tests if needed.

How does Snap-on® help?

Fast-Track® Troubleshooting Workflow, Guided Component Tests, and functional tests focus diagnostics on the specific vehicle and code, ensuring accurate repairs.