Snap-on® Diagnostic Software Exclusive

Prevent overheating and comebacks on modern VAG cooling systems

Cooling system faults following routine repairs are an increasingly common cause of repeat workshop visits on modern VAG vehicles. Water pump replacement, thermostat work and timing belt service can all introduce air into the cooling system, particularly on engines with a cambelt-driven water pump.

Unlike older systems, trapped air is not always purged by simply running the engine. Airlocks can remain within the radiator, heater matrix, coolant bypass circuits or auxiliary pumps, leading to overheating, warning lamps, poor cabin heat and fault codes being logged shortly after the vehicle leaves the workshop.

To address this, many VAG vehicles are equipped with a vehicle-controlled coolant bleed routine that must be completed after cooling system work. On supported models, Snap-on® Diagnostic Software provides access to this OEM Engine Coolant Bleed Function, allowing technicians to carry out the correct post-repair procedure in line with manufacturer requirements.

Applicable vehicles

This special function is used on many modern VAG vehicles with cambelt-driven water pumps. Highlighted applications include Volkswagen Scirocco (2008–2017) and Škoda Kodiaq (2017–2024).

These vehicles are particularly sensitive following VAG water pump replacement during timing belt service, where air can easily remain trapped within the cooling system, radiator, thermostat housing or coolant bypass circuits.

Why the coolant bleed function is critical

After replacing a belt-driven water pump, thermostat or radiator, running the OEM coolant bleed function is essential to remove trapped air from the system.

If the procedure is not carried out:

These issues often appear shortly after repair, leading to avoidable comebacks.

How the Engine Coolant Bleed Function operates

Once accessed through the Snap-on® diagnostic tool, the OEM bleed routine actively purges air from the cooling system using controlled engine and pump operation.

During the procedure:

This ensures antifreeze and coolant are correctly distributed throughout the system, reducing the risk of overheating when the vehicle returns to service.

Symptoms of an incorrect coolant bleed procedure

If the coolant pump or auxiliary water pump is not bled correctly, technicians may observe:

-

In some cases, heater performance issues may also be caused by silicate bags breaking down, allowing debris to block the heater matrix. Correct bleeding helps confirm whether the fault is circulation-related before replacing further components.

Tech Tip: Silicate Bags and Expansion Tank Considerations

Some VAG vehicles are fitted with ‘silicate bags’ or capsules in the expansion tank (see photo). While there has never been an official TSB, it is widely regarded as a known recommendation to either replace the expansion tank with a non-‘Mit Silikat’ version or remove the capsules entirely. This helps prevent the silicate from entering the coolant system and potentially blocking the heater matrix, an issue commonly observed on later Mk6 Golf models.

For vehicles no longer under warranty, it is also acceptable to change the antifreeze specification from G13 (purple/lilac), which has low or zero silicate, to G12+ (orange/red). G12+ already contains a higher level of suspended silicate mixed with de-ionised water at a 50/50 ratio, which does not cause heater matrix blockages while maintaining proper coolant performance.

This precautionary measure can reduce circulation issues and helps confirm whether any heater performance problems are related to circulation or contamination, supporting a more accurate post-repair diagnosis.

Diagnostic trouble codes to watch for

A common DTC associated with incorrect bleeding includes:

In many cases, this code points to trapped air rather than a failed water pump or thermostat.

Correct pre-fill procedure: vacuum filling is essential

Before running the bleed routine, the coolant system must be pre-filled under vacuum, in line with OEM requirements.

Using a tool such as the Snap-on Cooling Refill/Retention Tool (RADKITULTRA) helps to:

Skipping vacuum pre-fill significantly increases the risk of persistent airlocks and overheating complaints.

Hybrid and electric vehicle considerations

Many hybrid and electric vehicles use auxiliary electric coolant pumps to circulate coolant around:

After refilling coolant on these systems, completing the appropriate bleed function via the diagnostic tool is essential to remove air and maintain correct thermal control across all circuits.

Secure Gateway access via Snap-on® Security Link

Vehicle manufacturers increasingly protect critical vehicle systems behind secure gateways to prevent unauthorised access and reduce cyber security risks. Certain diagnostic and service functions are only available through approved manufacturer access.

Snap-on® Security Link™ provides authorised access to OEM-secured vehicle modules directly through compatible Snap-on® diagnostic platforms. Once the required OEM registration process is complete, the diagnostic tool can communicate with secured vehicle networks, allowing supported procedures to be carried out in line with manufacturer requirements.

Secure access is supported for:

For VAG vehicles equipped with Secure Gateway (2021 model year and newer), access to the OEM Engine Coolant Bleed Function is supported in the UK via Snap-on® Security Link and is provided as a complementary solution, ensuring diagnostic and service procedures can be completed without interruption.

Ensure your Snap-on® car diagnostic tool is running the latest software version and connected to Wi-Fi to unlock full Security Link™ functionality.

Coolant Bleed Procedure – Operational steps

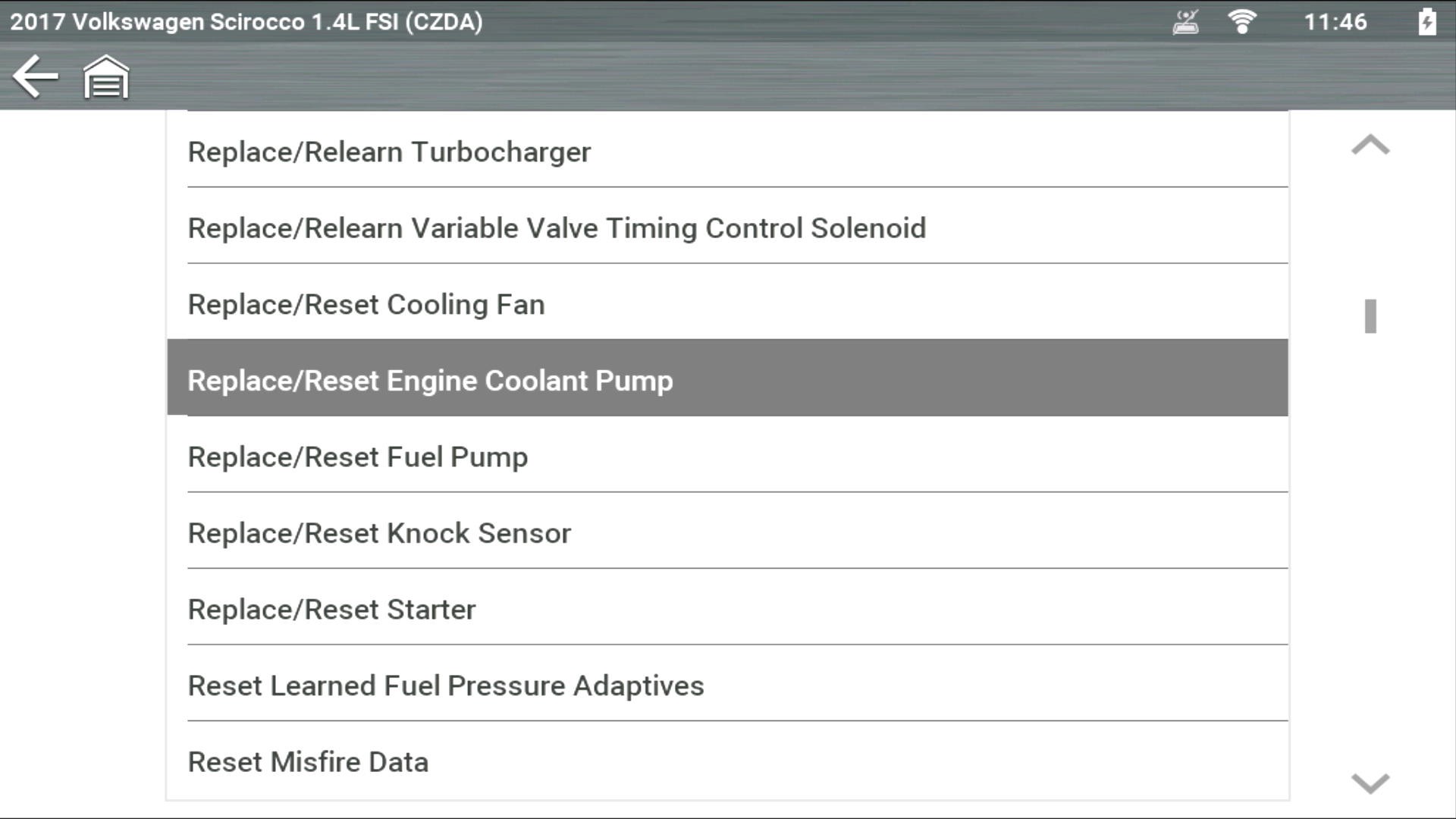

From the system selection menu:

-

Select Service resets and relearns

-

Select Replace/Reset engine coolant pump

a. Related TSBs may appear for this repair

3. Select Functional tests and calibrations

4. Select Coolant pump

a) Ensure ignition is ON and engine is OFF

b) Some actuators require the bonnet to be open

5. Select Continue

6. Select Start to begin the procedure

7. Once complete, select Continue to return to the previous menu

Coolant Bleed Routine: OEM-Guided Precision with Snap-on® Diagnostics

The coolant bleed routine is a vehicle-controlled function, but clear, guided access via Snap-on® Diagnostic Software allows technicians to carry out the OEM procedure with confidence. Correct use of this function helps reduce overheating issues, protects water pumps and auxiliary components, and minimises comebacks following timing belt and water pump replacement.